In the realm of metal ore crushing, challenges such as blockages, rapid wear, and unstable production are all too common. High - mud - content materials, in particular, pose significant threats to the operational efficiency of jaw crushers. This article delves deep into the impact of high - mud - content materials on the efficiency of jaw crushers and presents practical solutions through the structural optimization advantages of Zhengzhou Kuanglian's PEW jaw crusher.

In actual production scenarios, high mud content in metal ores can lead to a series of issues. For instance, the high mud content can cause jamming in the crusher. The sticky mud adheres to the inner walls of the crusher, reducing the effective space for material passage and eventually leading to blockages. Additionally, the high - mud - content materials accelerate the wear of liners. The abrasive nature of the mud, combined with the constant friction during the crushing process, shortens the lifespan of the liners. As a result, the production output becomes unstable, with frequent fluctuations in the amount of crushed ore.

Zhengzhou Kuanglian's PEW jaw crusher addresses these challenges through several structural improvements. Firstly, the V - shaped crushing chamber design is a game - changer. The V - shaped structure allows for a more efficient crushing process, as it provides a larger opening at the top for easy material entry and a smaller opening at the bottom for better control of the particle size. This design reduces the likelihood of blockages and increases the overall crushing efficiency.

Secondly, the use of wear - resistant alloy moving jaw plates significantly improves the durability of the crusher. These plates can withstand the high - intensity wear caused by high - mud - content materials, reducing the frequency of replacements and thus lowering the maintenance costs. On average, compared to traditional jaw plates, the wear - resistant alloy moving jaw plates can extend the service life by up to 30%.

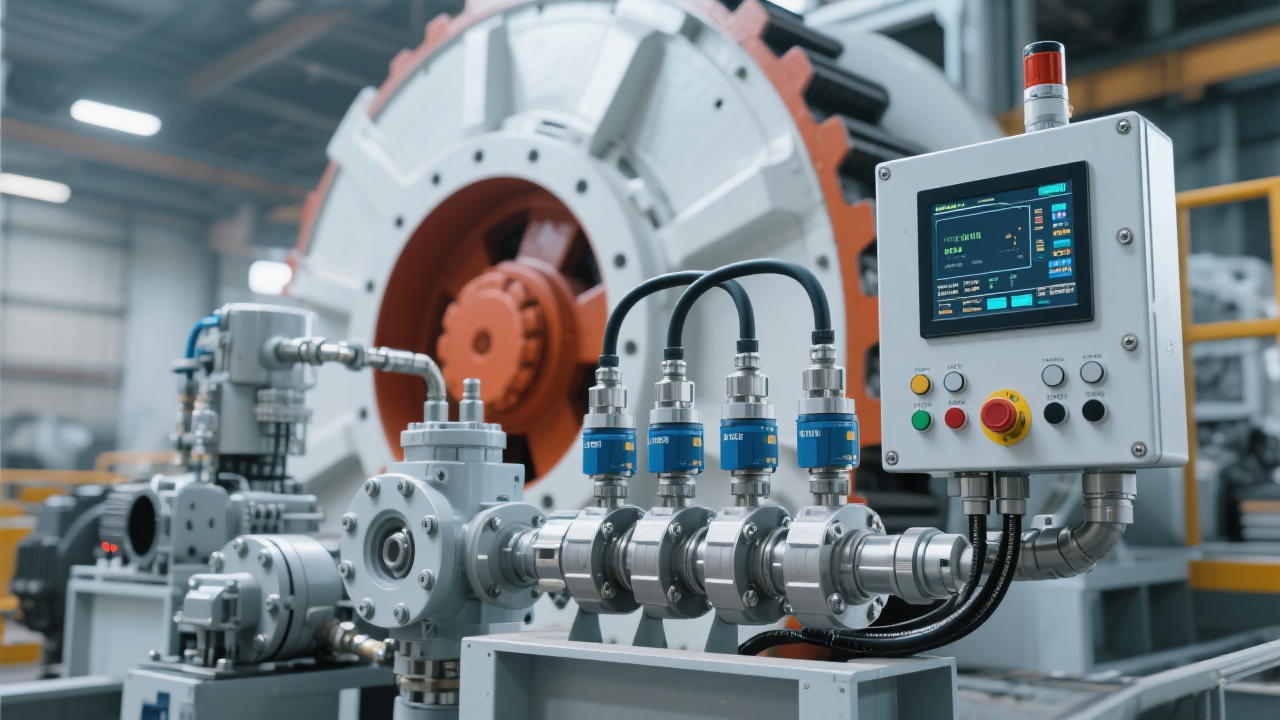

Moreover, the PEW jaw crusher is also equipped with an automatic material - clearing device. This device can effectively remove the sticky mud adhered to the inner walls of the crusher, ensuring smooth material flow and stable production. In terms of the feed opening, its size is optimized to match the characteristics of high - mud - content materials, preventing large - sized materials from entering and causing blockages.

In real - world applications, it is crucial to identify early abnormal signals of the crusher. For example, changes in vibration frequency and current fluctuations can indicate potential problems. By analyzing these signals, operators can take preventive measures in a timely manner. One real - world case shows that by monitoring the vibration frequency, the maintenance team was able to detect a loose component in the crusher in advance. After timely repair, the crusher's normal operation was restored, avoiding a potential shutdown and significant production losses.

A preventive maintenance plan is essential for the long - term stable operation of the PEW jaw crusher. This plan should include regular inspections, lubrication, and replacement of worn - out parts. By following a strict maintenance schedule, the crusher's service life can be extended, and the production efficiency can be maintained at a high level. According to industry data, mines that implement a comprehensive preventive maintenance plan can reduce equipment downtime by up to 20% and increase production efficiency by about 15%.

Engineer's Practical Advice: "Regularly check the wear of the liners and replace them in time. Also, pay close attention to the operation parameters of the crusher, such as temperature and pressure, to ensure its stable operation."

To enhance user engagement, we encourage you to share your experiences and ask questions in the comment section below. Whether you are facing similar problems in your mine or have some insights to share, your participation will contribute to a more in - depth discussion and a better understanding of the PEW jaw crusher.

In conclusion, Zhengzhou Kuanglian's PEW jaw crusher offers a comprehensive solution to the challenges in metal ore crushing, especially for high - mud - content materials. By leveraging its structural optimization advantages and following a preventive maintenance plan, mining enterprises can improve the stability and continuity of their production, achieving a win - win situation in environmental protection and economic benefits. Click here to learn more about how the PEW jaw crusher can助力业务可持续发展 and让客户在环保与经济效益上双丰收!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)