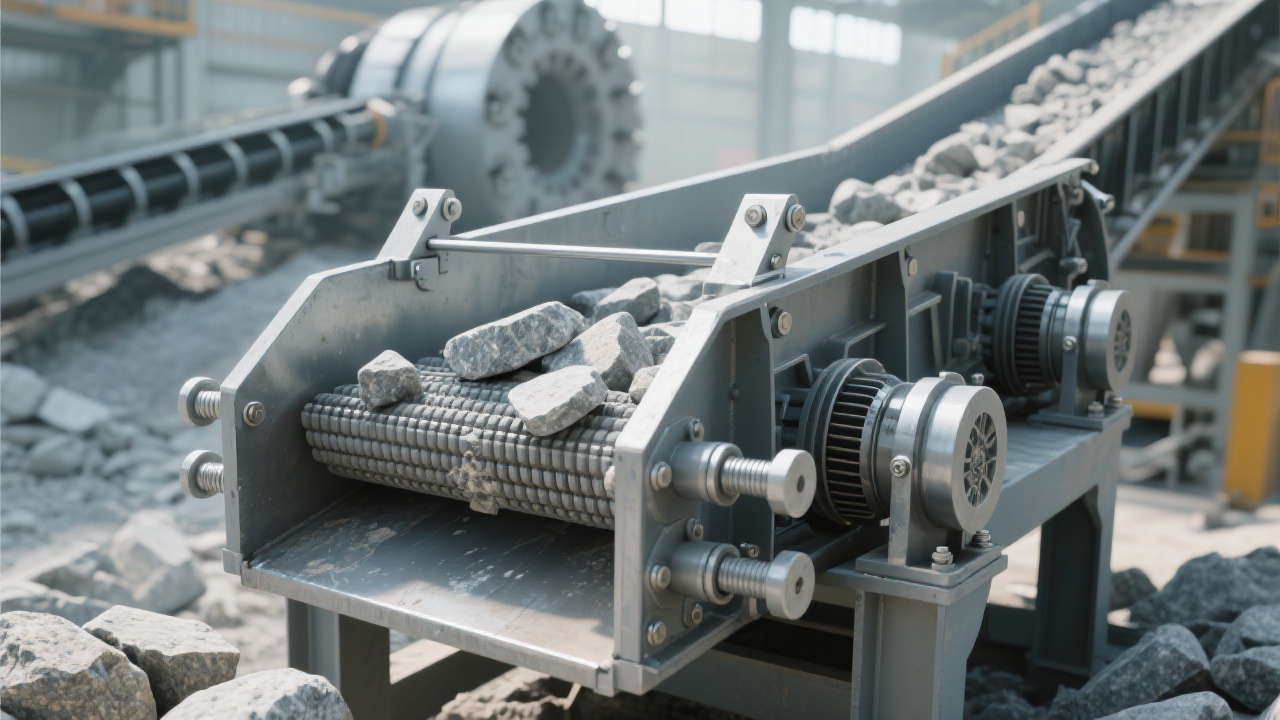

In the large aggregate production industry, high-yield crushing equipment is the key to improving production efficiency and reducing costs. Aggregate plants are constantly seeking equipment that can handle large volumes of ore with high efficiency and stability. The C6X Jaw Crusher emerges as a remarkable solution to meet these core needs.

The C6X Jaw Crusher is equipped with advanced technology and excellent design. It has a large feed opening, which can accommodate large-sized ore, and a high crushing ratio, up to 6:1. This means that it can break down large rocks into smaller, more manageable pieces in one go. Its processing capacity can reach up to 1000 tons per hour, which is very suitable for large-scale aggregate production. For example, in a large aggregate plant in Southeast Asia, after using the C6X Jaw Crusher, the daily production increased from 3000 tons to 5000 tons, a significant 66.7% increase.

The C6X Jaw Crusher features an optimized structure design. The use of a non-welded frame structure significantly improves the overall strength and reliability of the equipment. The adjustable discharge opening allows users to easily control the particle size of the output, meeting different production requirements. Moreover, the advanced crushing chamber design ensures uniform stress distribution, reducing wear and tear on the components and prolonging the service life of the equipment.

High-quality materials are used in the manufacturing of the C6X Jaw Crusher. The movable jaw and fixed jaw are made of high-manganese steel, which has high hardness and wear resistance. The bearings are of international high-quality brands, ensuring smooth operation and long service life. The advanced manufacturing process also guarantees the precision and stability of the equipment, reducing the failure rate and maintenance costs.

In different international markets, the C6X Jaw Crusher has shown excellent performance. In the Middle East, where there are large amounts of hard limestone, the C6X Jaw Crusher has been widely used. A local aggregate plant reported that the equipment has high stability, with a failure rate of less than 1% per year. In Africa, where the ore types are complex, the C6X Jaw Crusher can adapt well to different ore characteristics. A mining company in Africa said that the crusher can effectively break down various ores, and the output particle size is very uniform, which meets the high - quality requirements of the local construction industry.

The C6X Jaw Crusher has good adaptability to different ore types, including hard ores such as granite and basalt, as well as medium - hard ores such as limestone and dolomite. Its powerful crushing force and stable operation ensure high - efficiency crushing in various ore environments. For example, when processing granite, the C6X Jaw Crusher can maintain a high crushing efficiency, and the wear of the crushing cavity is relatively small. The stability of the equipment is also reflected in its continuous operation ability. It can run continuously for 24 hours a day, 7 days a week, with only regular maintenance required.

During the installation process, it is necessary to ensure a flat and solid foundation. The installation team should follow the detailed installation instructions provided by the manufacturer. Commissioning is also a crucial step. After installation, a series of tests should be carried out, including no - load test and load test, to ensure the normal operation of the equipment. In daily operation, regular inspection and maintenance are essential. For example, checking the lubrication system, tightening bolts, and replacing worn - out parts in time can ensure the long - term stable operation of the equipment. In a case of an aggregate plant in South America, by following these maintenance procedures, the service life of the C6X Jaw Crusher was extended by 30%.

With the development of the aggregate industry, the demand for high - quality aggregates is increasing. Upgrading equipment is an inevitable trend. The C6X Jaw Crusher represents the latest technological achievements in the field of crushing equipment. By using this advanced equipment, aggregate plants can improve production efficiency, reduce costs, and enhance market competitiveness. It is a forward - looking investment for aggregate producers to keep up with the industry development trend.

Do you have any questions about the C6X Jaw Crusher or aggregate plant equipment upgrading? Leave your questions below, and we will answer them as soon as possible.

Are you interested in upgrading your aggregate plant equipment to achieve higher efficiency and profitability? Click here to learn more about the C6X Jaw Crusher and how it can transform your business!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)