In the processing of chemical raw materials, the adjustment of the discharge port of an impact crusher directly affects the consistency of product particle size and production efficiency. Traditional manual adjustment methods come with a host of problems. Firstly, they are time - consuming. Workers may spend hours or even days fine - tuning the discharge port, which significantly slows down the production process. Secondly, the error rate is high. Manual adjustments rely on human judgment, and slight errors can lead to significant fluctuations in particle size. These fluctuations not only affect product quality but may also cause rework or even equipment overload, increasing production costs and reducing efficiency.

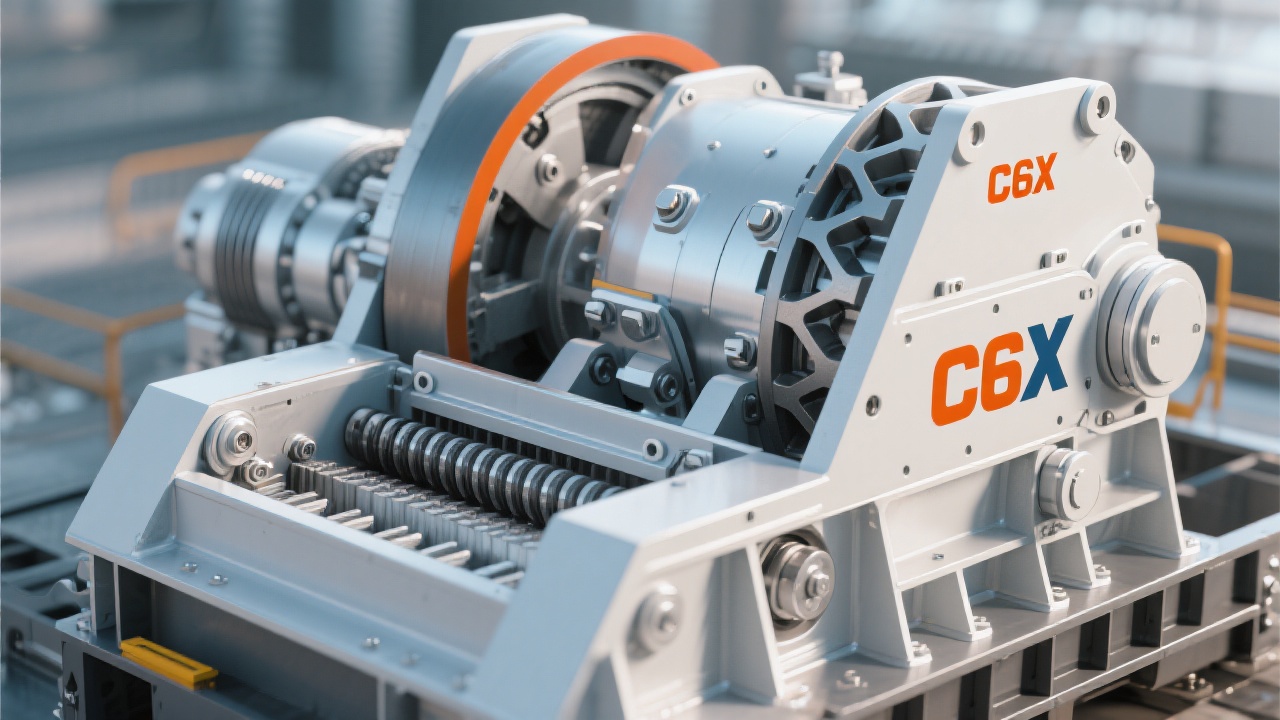

The PFW impact crusher uses a double - wedge adjustment mechanism, which offers a revolutionary solution to the above problems. The double - wedge structure consists of two wedges that work in tandem. When the hydraulic or mechanical system is activated, the wedges move relative to each other, allowing for rapid and stepless adjustment of the discharge port. This mechanism is highly precise, reducing the error rate to less than 5%. The hydraulic/mechanical linkage works in a coordinated manner. The hydraulic system provides the driving force, while the mechanical part ensures stable operation. This combination allows for quick and accurate adjustments, ensuring that the crusher can adapt to different production requirements.

Different chemical raw materials have different physical properties, so the adjustment parameters of the discharge port also vary. For limestone, a common chemical raw material, when the hardness is around 3 - 4 on the Mohs scale, the recommended initial adjustment of the discharge port is between 20 - 30 mm. As the production progresses, the adjustment can be fine - tuned according to the actual particle size. For coal gangue, with a relatively lower hardness of about 2 - 3 on the Mohs scale, the initial discharge port adjustment can be set at 15 - 25 mm. These parameters are based on years of practical experience and can be adjusted according to specific production conditions.

To help you better understand the adjustment process, we have prepared a debugging flowchart for typical application scenarios. This flowchart includes key node judgment criteria, such as how to determine whether the particle size meets the requirements and when to stop the adjustment. By following this flowchart, you can quickly and accurately complete the adjustment of the discharge port, improving production efficiency and product quality.

A chemical plant once faced problems with unstable particle size and low production efficiency. After optimizing the adjustment of the discharge port of their PFW impact crusher using the methods described in this article, they achieved remarkable results. The production line stability increased by 30%, and the product quality improved significantly. The rework rate decreased by 20%, and the equipment overload situation was effectively controlled, saving a large amount of production costs.

A: There could be several reasons. Firstly, the raw material properties may have changed. Secondly, the adjustment may not be accurate enough. It is recommended to check the raw material and re - adjust the parameters according to the actual situation.

A: You can use a particle size analyzer to measure the particle size. In addition, you can also observe the appearance and performance of the product. If the product meets the production requirements, it indicates that the ideal particle size has been reached.

Precise control of the discharge port of the impact crusher is the key to efficient production. By using the PFW impact crusher's double - wedge adjustment mechanism, you can achieve rapid and accurate adjustment, which not only improves production efficiency but also saves energy and extends the service life of the equipment. If you want to learn more about the technical advantages of the PFW impact crusher and how it can transform your production line, click here to get in touch with us and start your journey towards more efficient chemical raw material processing.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)