Efficient metal ore crushing is critical for mining operations aiming to maximize throughput while minimizing downtime. However, frequent jamming of iron ore crushers — especially jaw crushers — disrupts production flow, inflates maintenance costs, and reduces overall yield. This article delves into the root causes of crusher blockages, analyzing from the perspectives of material properties, equipment design, and operational best practices. Leveraging insights from the innovative Zhengzhou Kuanglian PEW Jaw Crusher, with its upgraded V-shaped crushing cavity and advanced wear-resistant materials, we outline actionable solutions for stable, high-efficiency crushing systems. Field engineers’ practical experiences are incorporated to help operators proactively identify early warning signs and maintain continuous uptime.

Crusher jamming often stems from a combination of challenging ore characteristics and mechanical limitations. Iron ore is frequently hard, abrasive, and prone to moisture variation, which impacts its flowability inside the crusher chamber. Key factors include:

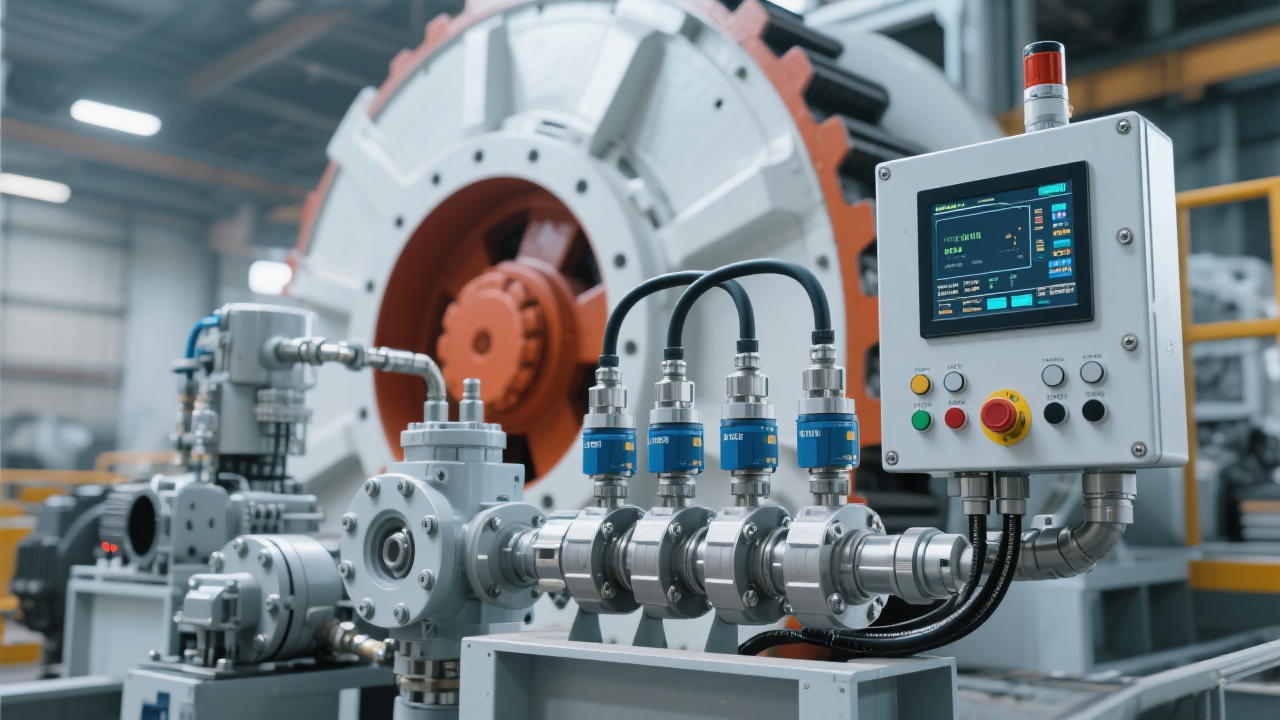

The PEW Jaw Crusher by Zhengzhou Kuanglian addresses these challenges through:

| Feature | Benefit |

|---|---|

| V-Shaped Crushing Cavity | Improves material grip and provides self-cleaning action reducing blockage risk by 30% |

| High-Manganese & Anti-Abrasion Liners | Extends wear life up to 40%, maintaining consistent crusher gap and performance |

| Optimized Feed Opening & Hydraulic Adjustment | Facilitates smooth feeding, faster clearing of blockages, and easy gap adjustment |

These technical upgrades have been validated in multiple iron ore operations, achieving a 10-15% throughput increase and lowering unplanned downtime by nearly 25%.

Beyond design improvements, the way crushers are operated significantly impacts the frequency of jamming incidents. Proven operational guidelines include:

Incorporating standard operating procedures (SOPs) crafted around these points can reduce blockage incidents by more than 35% according to field data from major iron ore mines.

Experience from frontline engineers confirms that early detection is pivotal. Typical indicators include:

Prompt response actions encompass immediate feed rate adjustment, vibration monitoring, and if necessary, hydraulic opening for manual blockage clearing—all significantly reducing downtime from hours to minutes.

For mining enterprises targeting enhanced profitability through reliable and efficient ore processing, Zhengzhou Kuanglian’s PEW Jaw Crusher represents a technologically advanced solution. Its superior structural design, durability under harsh conditions, and easy maintenance translate directly into:

Experience the power of innovation that empowers your iron ore crushing performance — Explore Zhengzhou Kuanglian PEW Jaw Crusher Benefits & Request a Customized Quote

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)