.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the metal ore crushing industry, jaw crushers play a crucial role in the primary crushing process. They are widely used due to their high efficiency and reliability. However, like any machinery, jaw crushers are prone to several common problems such as blockages, wear and tear, and fluctuations in production output.

Take, for example, a medium - sized metal ore mine in South Africa. They were using a traditional jaw crusher and faced frequent blockages, which led to a significant decrease in production efficiency. The downtime for clearing blockages was averaging about 2 - 3 hours per week, resulting in a loss of approximately 10% of their weekly production capacity.

The Zhengzhou Kuanglian PEW Jaw Crusher is equipped with advanced technology that allows for a higher crushing ratio. It can handle large - sized metal ores with a maximum feed size of up to 1200mm and reduce them to a smaller size in one go. The crusher's motor power is carefully calibrated to ensure stable operation, with power ranging from 55kW to 315kW depending on the model.

One of the most significant features of the PEW Jaw Crusher is its unique "V" - shaped crushing chamber. This design not only increases the feed opening but also provides a more efficient crushing path. The "V" - shaped chamber allows the ore to be crushed more evenly, reducing the likelihood of blockages. In addition, the crusher uses high - quality wear - resistant materials in its key components, such as the jaw plates. These materials can withstand the high - intensity impact and friction during the crushing process, extending the service life of the equipment.

.jpg)

Blockages in jaw crushers are often caused by over - feeding, improper particle size distribution of the feed ore, or the presence of non - crushable materials. For instance, if the feed rate is too high, the crusher may not be able to process the ore in time, leading to a build - up of materials in the crushing chamber.

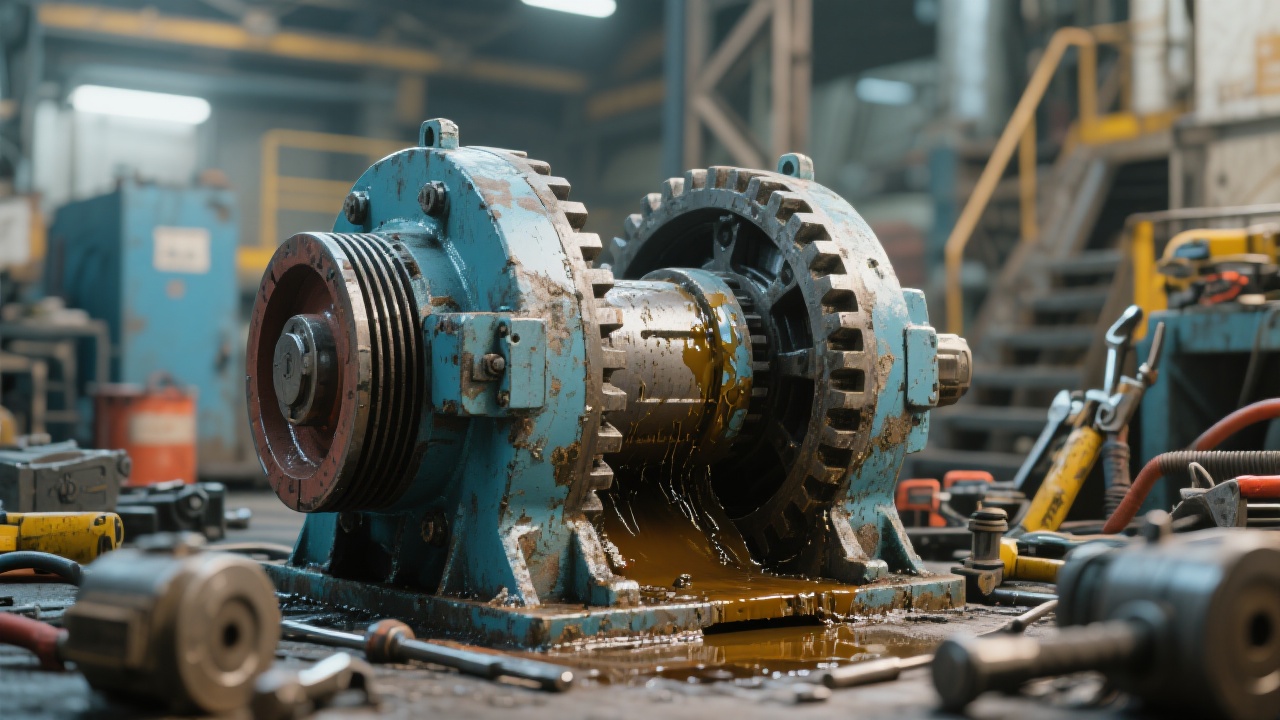

Wear and tear mainly occur on the jaw plates, liners, and bearings. The constant impact and friction between the ore and the crusher components gradually erode these parts. In a copper ore mine in Chile, the jaw plates of their old crusher needed to be replaced every 2 - 3 months, which added a significant cost to the operation.

Fluctuations in production output can be due to various factors such as changes in the hardness of the ore, equipment malfunctions, or improper operation. If the ore hardness suddenly increases, the crusher may struggle to maintain the same production rate.

| Problem | Root Cause | Example |

|---|---|---|

| Blockages | Over - feeding, improper particle size, non - crushable materials | A mine in Australia faced blockages when large pieces of iron ore entered the crusher |

| Wear and Tear | Constant impact and friction | Jaw plates in a zinc ore mine wore out quickly |

| Production Output Fluctuations | Ore hardness change, equipment malfunction, improper operation | A nickel ore mine experienced output drops during equipment maintenance |

Regularly inspect the key components of the crusher, such as the jaw plates, bearings, and belts. Check for signs of wear, cracks, or loose connections. For example, the bearings should be inspected every 500 operating hours for proper lubrication and any signs of overheating.

Proper lubrication is essential for the smooth operation of the crusher. Use high - quality lubricants and follow the manufacturer's guidelines for lubrication intervals. The lubrication of the bearings can significantly reduce friction and extend their service life.

Keep the crusher clean to prevent the accumulation of dust and debris. Regularly clean the crushing chamber and the surrounding areas. This can help prevent blockages and improve the overall performance of the equipment.

Control the feed rate and particle size of the ore. Do not over - feed the crusher. Use a vibrating feeder to ensure a uniform feed of ore into the crusher. This can help prevent blockages and ensure stable operation.

Follow the correct startup and shutdown procedures. Start the crusher after all the auxiliary equipment is running smoothly, and shut it down in the reverse order. This can prevent damage to the equipment.

A gold ore mine in Canada replaced their old jaw crusher with the Zhengzhou Kuanglian PEW Jaw Crusher. Before the replacement, they were facing frequent blockages and high wear - and - tear costs. After using the PEW Jaw Crusher for 6 months, the blockage frequency decreased by 80%, and the wear - and - tear cost was reduced by 40%. The production efficiency also increased by about 15%.

In conclusion, the Zhengzhou Kuanglian PEW Jaw Crusher offers significant advantages in terms of efficiency, stability, and durability in the metal ore crushing process. By following the maintenance tips and operation precautions provided in this article, you can further enhance the performance of the equipment and achieve higher production efficiency.

Are you looking to upgrade your metal ore crushing equipment? Click here to learn more about how the Zhengzhou Kuanglian PEW Jaw Crusher can transform your mining operations!

Do you have any questions about the Zhengzhou Kuanglian PEW Jaw Crusher or metal ore crushing in general? Leave your questions below, and our experts will answer them as soon as possible!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)