.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the granite aggregates industry, efficient production hinges not just on equipment selection—but on how well raw material characteristics align with crushing parameters. In my 18 years of working with mining and construction clients across 30+ countries, I’ve seen countless projects fail due to mismatched design logic—especially in non-metallic mineral processing.

For granite, which typically has a Mohs hardness of 6–7 and high compressive strength (up to 300 MPa), proper crushing sequence is critical:

| Crushing Stage | Recommended Equipment | Optimal Feed Size (mm) | Energy Efficiency Gain vs. Old Models |

|---|---|---|---|

| Primary | PEW Jaw Crusher | 150–300 | +25–30% |

| Secondary | HP Cone Crusher | 50–150 | +15–20% |

A real-world case from a quarry in Portugal illustrates this point: Their granite had unusually high silica content (≈75%), leading to excessive wear on standard jaw plates. After switching to PEW jaw crushers with hardened manganese steel liners and adjusting the closed-side setting from 80 mm to 65 mm, they reduced liner replacement frequency by 40% while increasing output by 18%.

This shows that even small adjustments in gap settings or eccentric speed can dramatically impact both product quality and machine longevity when dealing with abrasive materials like granitic rock.

.jpg)

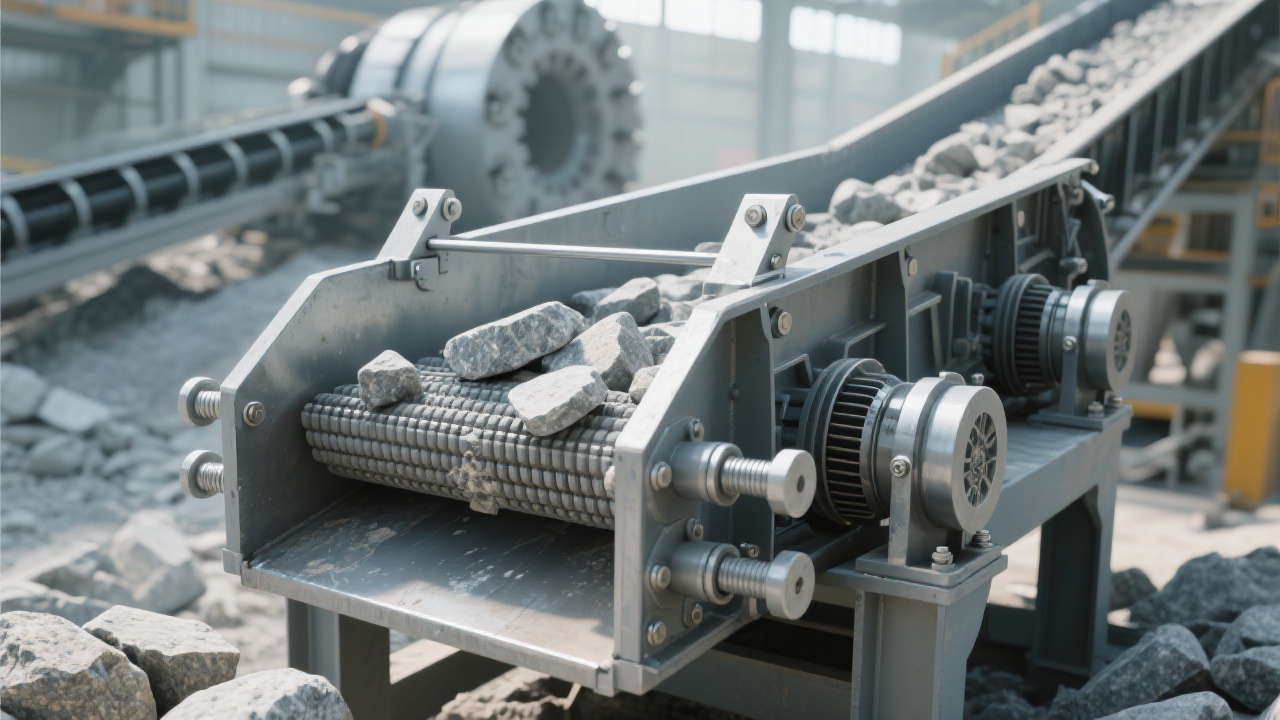

The efficiency of any stone crushing line depends on seamless integration between components. For example, using a vibrating screen with a 10 mm aperture immediately after the PEW jaw crusher ensures only properly sized feed reaches the cone crusher—reducing unnecessary energy consumption and mechanical stress.

One client in Mexico achieved a 12% improvement in overall system uptime by synchronizing the screening cycle with the jaw crusher’s feed rate—based on actual load data collected over three months of operation.

If you're designing or optimizing a granite aggregates line, don't treat crushing as a standalone task—it's a system-wide challenge. The key lies in understanding your raw material, selecting the right tools (like 郑州矿联 PEW jaw crusher with its high reduction ratio and low energy use), and fine-tuning the entire process together.

Need help tailoring your setup to specific granite properties? Get a free technical consultation now →

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)