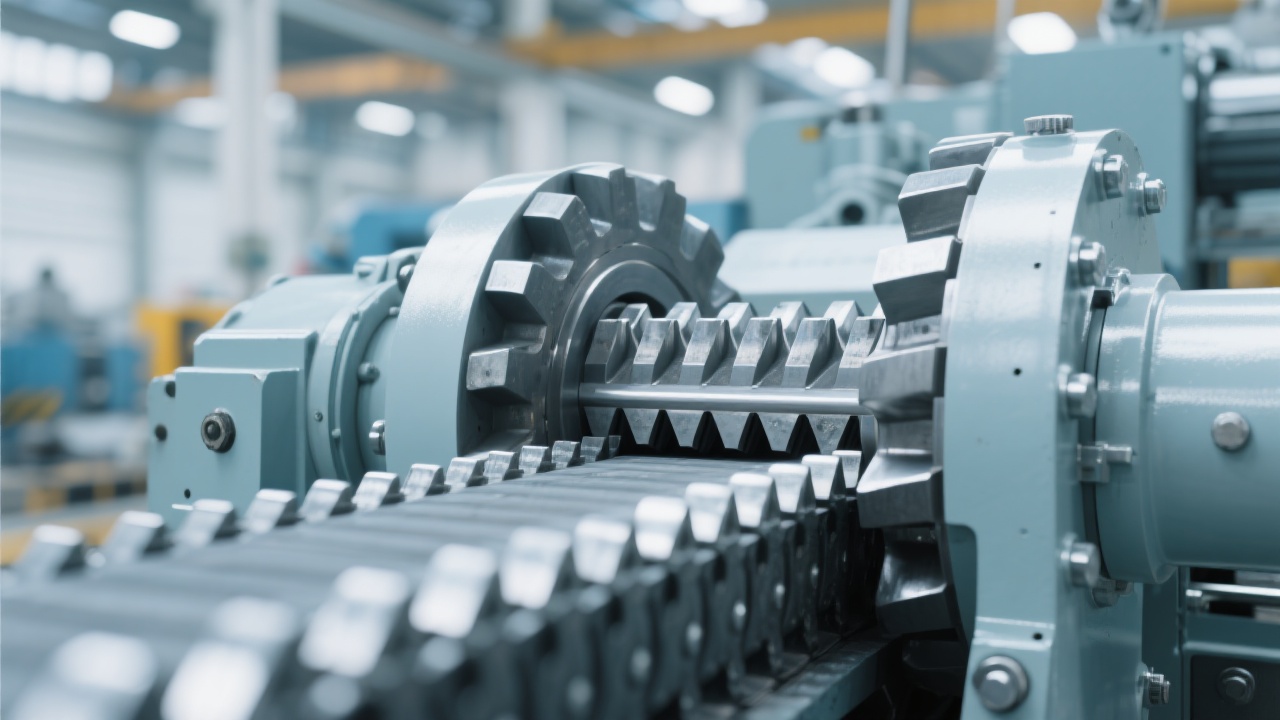

In modern mineral processing plants, achieving consistent product gradation while minimizing manual intervention is no longer optional—it’s a competitive necessity. The double wedge adjustment mechanism in Zhengzhou Kulin Machinery's PFW series impact crushers represents a significant leap forward in automated control systems for crushing operations.

Unlike traditional mechanical adjustments that require downtime and operator judgment, this dual wedge system uses hydraulic cylinders to precisely control two opposing wedges connected to the crusher’s movable jaw. This联动 (interlock) ensures real-time feedback between hydraulic pressure and physical position—reducing adjustment error by up to 70% compared to older models (based on internal testing at Kulin’s R&D lab).

For industries like cement production or coal processing, where feed material properties vary daily, precise granulometry matters. When handling limestone (hardness ~3 Mohs), operators should set the discharge opening at 30–40 mm for optimal throughput and particle uniformity. For more abrasive materials like coal gangue (hardness ~4–5 Mohs), reducing the gap to 25–35 mm helps minimize wear on liners while maintaining efficiency.

A major lime producer in Jordan implemented the dual wedge system across three PFW units. Within six months, they reported a 35% reduction in unplanned maintenance due to fewer manual interventions and better consistency in product size. Their team now spends less than 15 minutes per shift on adjustments versus over an hour previously.

Q: Can I adjust the gap during live operation?

Yes—with safety protocols enabled, the system allows dynamic adjustments without stopping the machine. This feature alone can boost productivity by 10–15% in high-volume facilities.

Q: What happens if there’s a sudden power loss?

The hydraulic system includes a backup accumulator that maintains minimum clearance for safe restart—preventing blockages and protecting components.

Ready to optimize your crushing line with intelligent automation? Explore how the PFW Impact Crusher from Zhengzhou Kulin Machinery delivers precision, reliability, and reduced operational costs—perfect for chemical, mining, and recycling sectors worldwide.

Discover the PFW Series Today →