As a technical leader or procurement decision-maker in the mining industry, you're well aware that the efficiency of metal ore crushing is closely tied to operational costs. One of the key factors in optimizing this process is the proper matching of the feed size for jaw crushers. In this article, we'll delve into the impact of different ore particle sizes within the 0–1020mm feed range on crushing efficiency, wear rate, and the shape of the discharged particles.

Different metal ores have unique physical and chemical properties, which directly influence the crushing process. For example, iron ore is relatively hard and dense, while bauxite is softer and more porous. These characteristics determine the type of crusher required and the optimal feed size. By understanding the relationship between ore characteristics and crushing process requirements, you can make more informed decisions when selecting a crusher.

Let's take a closer look at how different feed sizes (such as ≤300mm, 300–600mm, and 600–1020mm) affect the crushing process:

To illustrate these points, take a look at the following table, which shows the relationship between feed size, crushing efficiency, and wear rate based on industry data:

| Feed Size (mm) | Crushing Efficiency (%) | Wear Rate (%) |

|---|---|---|

| ≤300 | 85 | 15 |

| 300–600 | 80 | 20 |

| 600–1020 | 75 | 25 |

Let's look at some real-world examples to understand the risks of incorrect crusher selection and the benefits of improvement. One of our customers, a copper mining company, initially used a jaw crusher with an inappropriate feed size. This led to frequent equipment breakdowns, high maintenance costs, and reduced production efficiency. After consulting with our experts, they switched to a more suitable crusher and adjusted the feed size. As a result, their crushing efficiency increased by 20%, and their maintenance costs decreased by 30%.

"After working with [Company Name], we were able to optimize our crushing process and significantly improve our bottom line. Their expertise and support were invaluable." - [Customer Name], Copper Mining Company

To help you select the right crusher for your needs, we've developed a step-by-step methodology:

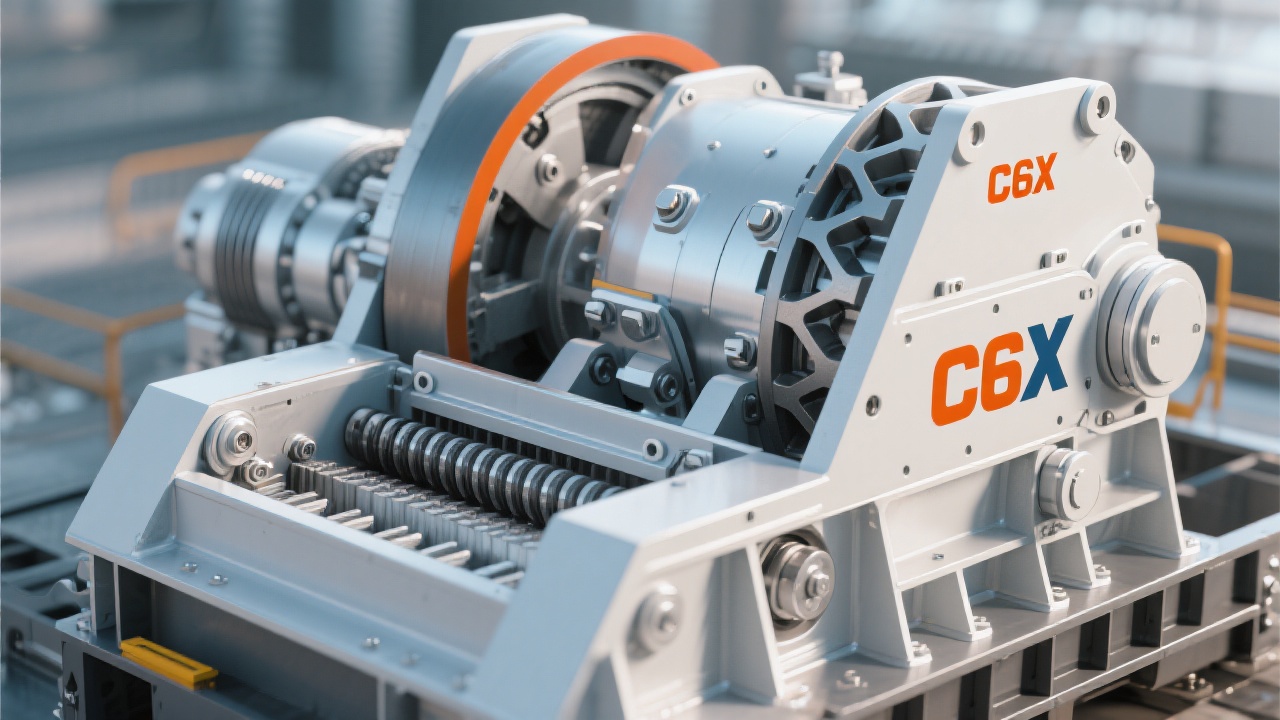

At [Company Name], we offer the PE jaw crusher, which is designed to provide stable performance and customizable solutions. With over 30 years of experience, our PE jaw crusher is capable of precisely matching various ore particle sizes. Whether you're crushing iron ore, copper ore, or bauxite, our crusher can help you achieve optimal results.

.jpg)

If you're interested in learning more about our PE jaw crusher or need help selecting the right crusher for your needs, please don't hesitate to contact us. Our team of experts is ready to assist you.

Have you ever encountered crushing problems due to improper feed size? We'd love to hear your experiences. Please leave a comment below and share your thoughts.