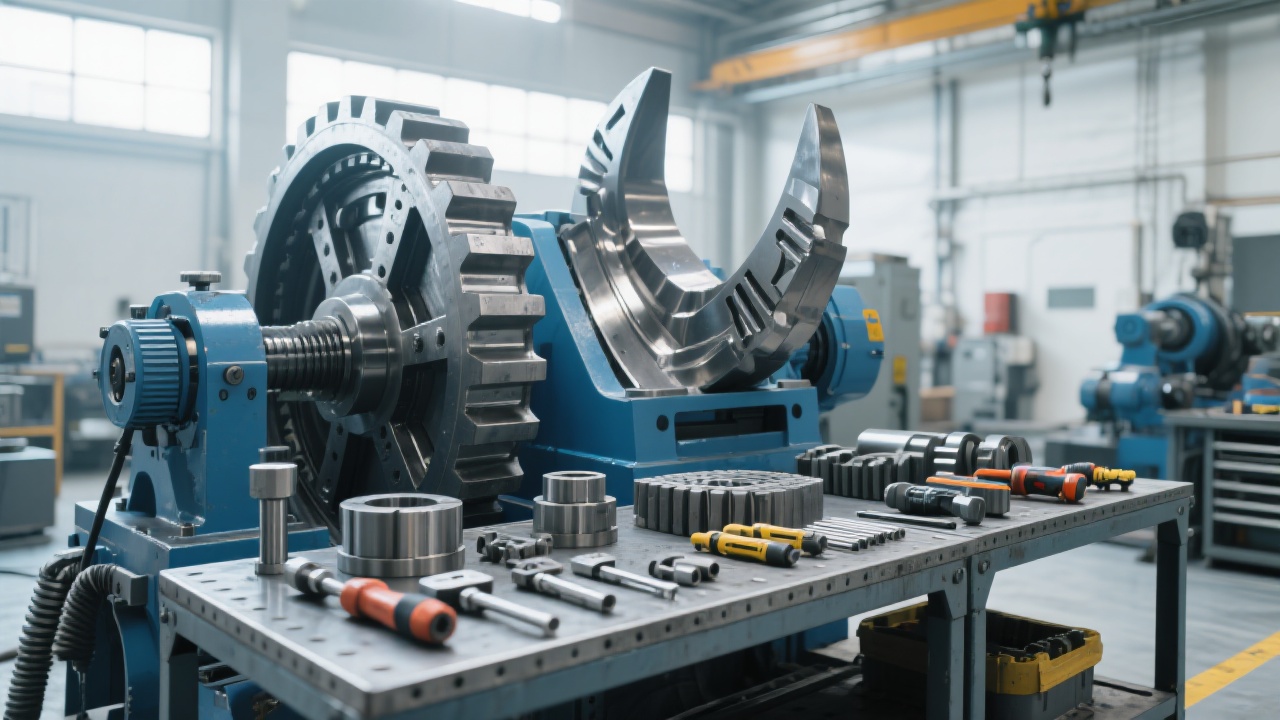

In the process of metal ore crushing, a critical question often arises: how can you scientifically select the feeding range of jaw crushers according to the original ore particle size? This article delves deep into the impact mechanisms of different particle sizes within the 0 - 1020mm feeding interval on crushing efficiency, wear rate, and the shape of the discharged particles. By integrating typical application cases of iron ore, copper ore, bauxite, etc., we offer a practical selection logic and operational guide. Our goal is to assist you in avoiding equipment overload or production capacity waste caused by improper feeding, thereby achieving stable production and maximizing long - term benefits.

Let's start with the analysis of the characteristics of the original ore. Different types of ores, such as hard ores and soft ores, have distinct impacts on the operating state of crushers. Hard ores, like some high - grade iron ores, require more energy to break. When fed into the crusher, they may cause greater wear on the crushing chamber and reduce the overall crushing efficiency if the feeding size is not properly controlled. On the other hand, soft ores, such as some low - grade bauxite, are relatively easier to break, but an improper feeding size can still lead to uneven particle size distribution in the output.

Based on actual operating condition data, we can compare the differences in crushing efficiency, equipment wear, and product particle shape among different feeding segments. For example, in the 0 - 300mm feeding segment, the crusher generally has a high crushing efficiency, with a relatively low wear rate on the equipment. The product particle shape is also more uniform. In the 300 - 600mm segment, the crushing efficiency may slightly decrease, and the wear on the equipment increases. As for the 600 - 1020mm segment, the crushing efficiency drops significantly, and the equipment may face higher wear risks, and the product particle shape may be less ideal.

| Feeding Segment (mm) | Crushing Efficiency | Equipment Wear | Product Particle Shape |

|---|---|---|---|

| 0 - 300 | High | Low | Uniform |

| 300 - 600 | Medium | Medium | Less Uniform |

| 600 - 1020 | Low | High | Non - Ideal |

Let's look at some real - world customer cases to better understand the importance of proper feeding size. For instance, in an iron ore project, due to over - sized feeding, the crusher frequently stopped, resulting in low production efficiency. After adjusting the feeding size to a reasonable range, the production capacity increased by 30%. This clearly shows that choosing the right feeding size can have a significant impact on the overall performance of the crushing process.

"Before adjusting the feeding size, our crusher was in a very bad state. We had to stop the production line frequently for maintenance. After following the advice on feeding size selection, the situation improved dramatically. Our production capacity increased, and the equipment maintenance cost decreased." - A satisfied customer

To help you select the right jaw crusher feeding range, we have developed a step - by - step methodology:

.jpg)

At Zhengzhou Kuanglian Machinery, we understand that every mining project is unique. That's why we offer customized PE jaw crushers with a global service experience. We have provided customized crushing solutions for over 137 countries' customers worldwide. Our crushers are designed to meet your specific needs, ensuring high - efficiency and stable operation.

If you are looking for a reliable jaw crusher solution for your metal ore crushing project, don't hesitate to contact us. Click here to get your专属选型建议 and take the first step towards maximizing your production capacity and long - term benefits.