The global sand and aggregate industry faces mounting challenges, including increasing operational costs, resource scarcity, and equipment wear that leads to frequent downtime. Traditional sand making machines often fall short in meeting the dual demands of high throughput and long-term durability. Consequently, there is a growing need for advanced equipment that delivers both high efficiency and energy savings while ensuring a significantly extended service life.

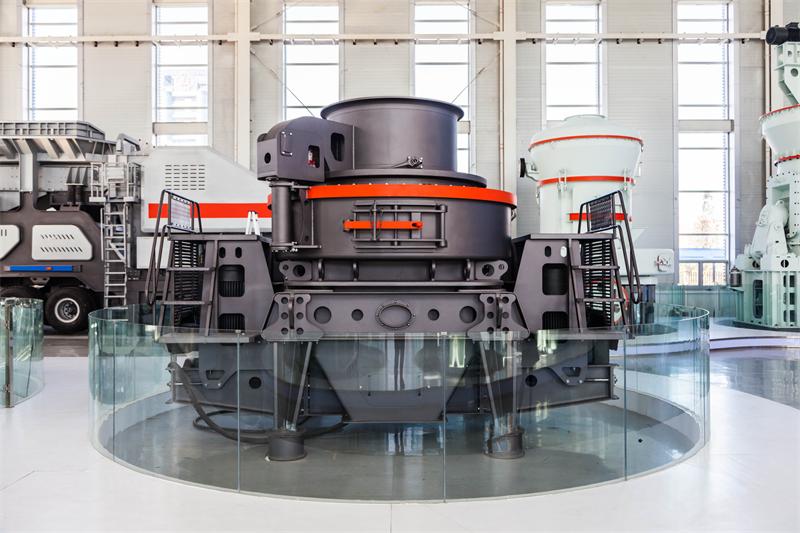

The VSI6X Sand Making Machine is a ground-breaking solution, integrating advanced numerical control (NC) machining technology and dual-motor drive systems to markedly improve operational reliability and lifespan. Through precise CNC manufacturing, core components achieve tighter tolerances and improved material properties, dramatically reducing premature wear.

The dual-motor drive not only balances load distribution but also optimizes power use. This innovative design lowers mechanical stress on key parts, resulting in an impressive 30% to 200% increase in equipment lifespan compared to conventional single-motor machines. Such performance gains translate directly into reduced maintenance frequency and lower overall operational expense.

Major enhancements in the VSI6X's structure focus on wear-resistant materials and component geometry optimization. For example, the impeller and rotor are manufactured through high-precision NC machining using special steel alloys that withstand abrasive impact and friction.

The incorporation of dual motors provides synchronized torque, reducing vibration and mechanical overload while improving operational smoothness. The result is a system that maintains peak performance longer, cutting downtime by nearly 40% according to field data.

| Parameter | Traditional VSI Machine | VSI6X Machine |

|---|---|---|

| Equipment Lifespan | 12,000 - 18,000 hours | 24,000 - 54,000 hours |

| Power Consumption (kW) | ~75 | ~62 |

| Maintenance Intervals | Every 800 hours | Every 1300 hours |

| Output Sand Quality | High fines content (8%-12%) | Low fines content (3%-6%) |

Several industry leaders in Asia and Europe have reported a noticeable boost in production efficiency—up to 20% higher throughput—while seeing a substantial reduction in downtime over 12-month operational cycles with the VSI6X.

One case study from a major construction material supplier showed that adopting VSI6X reduced annual maintenance costs by 35%, while the intelligent control system provided real-time diagnostics that enhanced operational safety and minimized unexpected failures.

The manufacturer behind the VSI6X leverages decades of R&D and a dedicated global service network to ensure comprehensive support throughout the equipment lifecycle. Their expertise in high-precision machining, combined with reliable dual-motor technology, places VSI6X at the forefront of intelligent, energy-efficient sand making solutions.

Through continuous innovation and client-focused service, this machine guarantees not only operational excellence but also peace of mind for procurement decision-makers aiming to maximize long-term return on investment.

For procurement specialists and operational leaders looking to enhance sand making efficiency while ensuring highly durable and energy-saving equipment, the VSI6X offers an unmatched solution. Experience the benefits of advanced numerical control machining, intelligent dual-motor drive, and optimized component longevity—all backed by trusted global service support.

Ready to transform your production capacity and reduce costs?

Get Detailed Specifications & Custom Consultation

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)