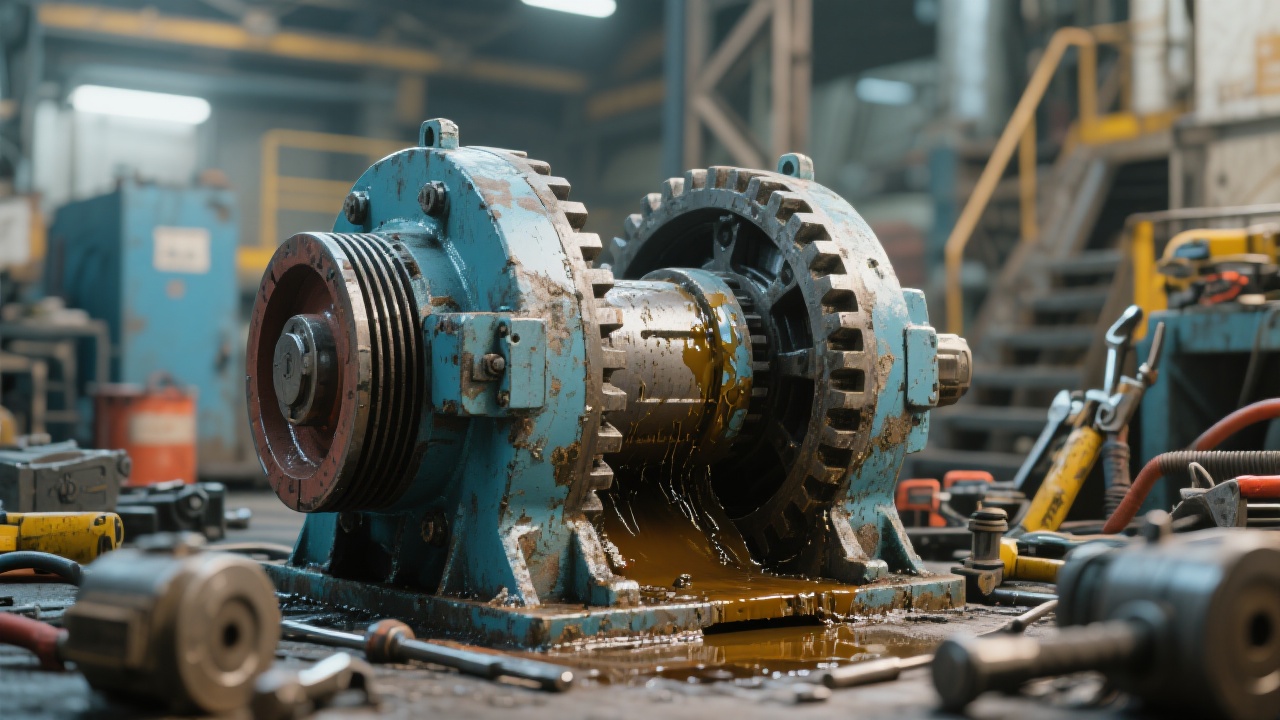

When it comes to metal ore crushing, many mining companies often encounter common equipment issues, such as blockages, accelerated wear of liners, and fluctuations in production. These problems not only affect the efficiency of the crushing process but also lead to increased maintenance costs and reduced economic benefits. In this article, we'll delve into the causes of these issues and explore practical solutions, with a focus on how regular adjustment of liner clearance can extend the service life of jaw crushers.

Several factors can impact the operation of jaw crushers during metal ore crushing. Material characteristics, such as uneven feeding, high mud content, and particle size distribution, play a significant role. Uneven feeding can cause blockages and uneven wear on the liners, while high mud content can lead to reduced crushing efficiency and increased wear. Additionally, improper equipment parameters and operating habits, such as failure to adjust the liner clearance in a timely manner, can also contribute to these problems.

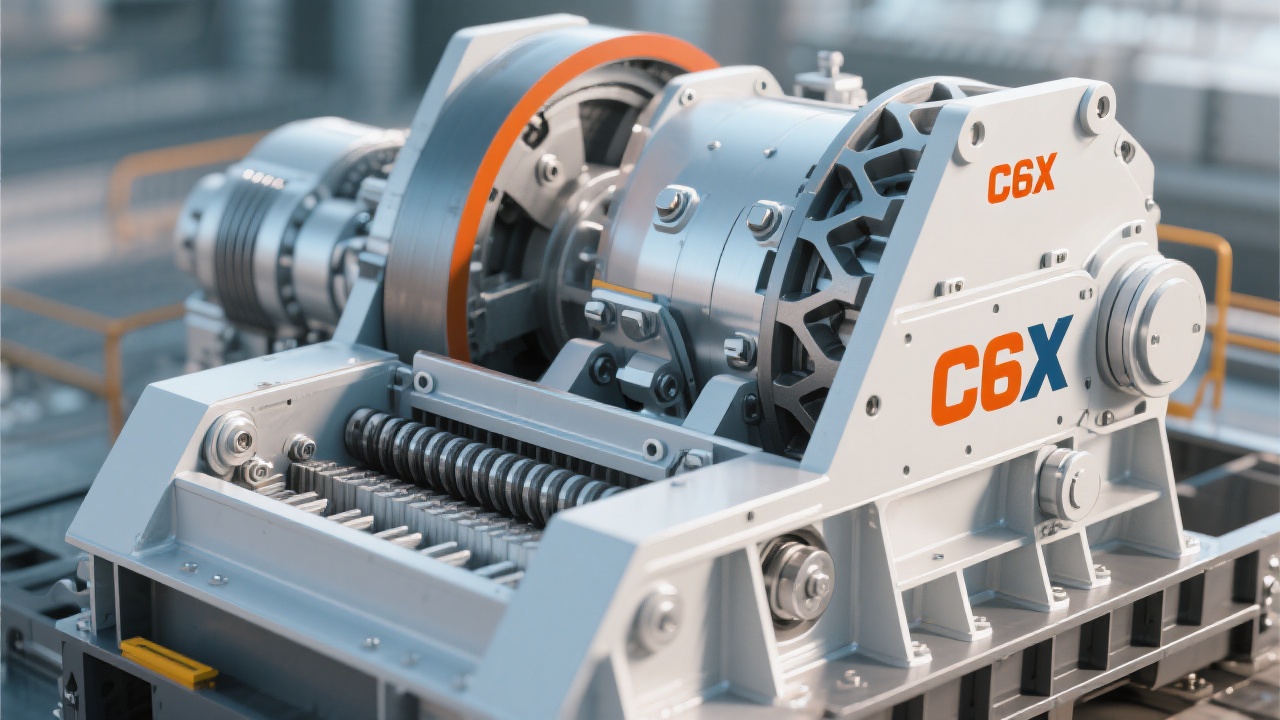

The Zhengzhou Kuanglian PEW Jaw Crusher is designed to address these challenges with its innovative structure and upgraded materials. The 'V'-shaped crushing chamber design provides a larger crushing area and higher crushing efficiency, while the use of wear-resistant alloy materials significantly extends the service life of the liners. These features make the PEW Jaw Crusher an ideal choice for metal ore crushing operations.

The 'V'-shaped crushing chamber design ensures that the material is evenly distributed during the crushing process, reducing the risk of blockages and improving the overall crushing efficiency. This design also allows for a more consistent product size, which is crucial for downstream processing.

The use of wear-resistant alloy materials in the PEW Jaw Crusher's liners provides superior resistance to wear and tear. Compared to traditional liners, these alloy liners can withstand higher impact forces and abrasive materials, resulting in a longer service life and reduced maintenance costs.

Based on the practical experience of front-line engineers, we've compiled a set of solutions and maintenance tips to help mining companies optimize the performance of their jaw crushers. One of the key recommendations is to regularly adjust the liner clearance.

Over time, the liners of a jaw crusher will wear down, causing the clearance between the liners to increase. This can lead to reduced crushing efficiency, increased vibration, and accelerated wear of other components. By regularly adjusting the liner clearance, you can ensure that the crusher operates at its optimal performance level, thereby extending its service life.

Front-line engineers recommend monitoring signals such as vibration and current to detect any abnormal operation of the crusher in advance. When the vibration or current exceeds the normal range, it may indicate that the liner clearance needs adjustment. To adjust the liner clearance, follow these steps:

To make this article more engaging and useful, we've included a table summarizing the key points and a Q&A section based on common questions from mining professionals.

| Problem | Cause | Solution |

|---|---|---|

| Blockages | Uneven feeding, high mud content | Ensure even feeding, reduce mud content, adjust liner clearance regularly |

| Accelerated liner wear | Improper liner clearance, abrasive materials | Regularly adjust liner clearance, use wear-resistant alloy liners |

| Production fluctuations | Uneven feeding, equipment malfunction | Ensure even feeding, perform regular maintenance and inspections |

Q: How often should I adjust the liner clearance?

A: It depends on the operating conditions and the type of material being crushed. As a general rule, we recommend checking the liner clearance at least once a month and adjusting it as needed.

Q: Can I use the PEW Jaw Crusher for other types of materials besides metal ores?

A: Yes, the PEW Jaw Crusher is suitable for a wide range of materials, including non-metallic ores, building materials, and recycled aggregates.

In conclusion, by understanding the causes of common equipment issues in metal ore crushing and implementing the solutions and maintenance tips provided in this article, mining companies can significantly improve the performance and efficiency of their jaw crushers. The Zhengzhou Kuanglian PEW Jaw Crusher, with its innovative design and high-quality materials, offers a reliable and cost-effective solution for metal ore crushing operations.

Are you ready to take your metal ore crushing operations to the next level? Click here to learn more about the Zhengzhou Kuanglian PEW Jaw Crusher and how it can benefit your business.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)