In modern chemical raw material processing, maintaining consistent particle size is paramount to ensuring product quality and reducing operational interruptions. The PFW impact crusher stands out with its advanced stepless discharge port adjustment system, which leverages hydraulic linkage principles combined with a unique dual-wedge structure design. This technological integration enables rapid and precise grain size control, enhancing both production flexibility and automation.

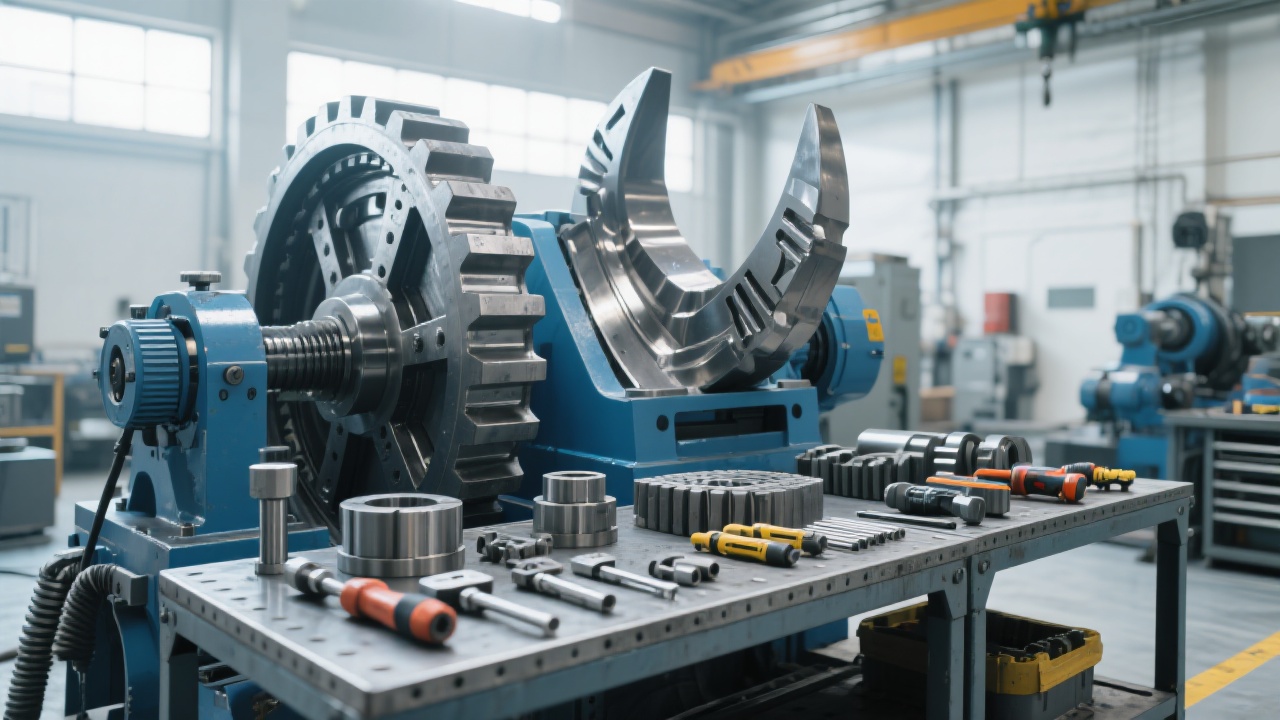

At the heart of the PFW impact crusher’s discharge port adjustment lies the dual-wedge structure. Unlike traditional single-mechanism systems, this design creates a balanced force distribution which achieves:

The hydraulic linkage works by transmitting fluid pressure changes into mechanical movement, ensuring the two wedges move symmetrically to open or close the discharge port. This interplay offers you intuitive and reliable control over the crusher’s output size.

Achieving steady particle size output is not only about having advanced technology—it demands precise operation. Below is the general workflow recommended for various raw materials like limestone and coal gangue:

Avoid common pitfalls such as abrupt discharge size changes or ignoring hydraulic system pressure fluctuations, which may cause equipment overload or inconsistent particle sizing.

In chemical raw material processing, crushing limestone for filler production requires strict tolerance in particle size. Our industry data shows that controlling particle sizes within ±2 mm of the target range reduces downstream rework rates by up to 35% and avoids up to 25% of unplanned downtime.

Common troubleshooting scenarios include uneven wedge movement caused by hydraulic fluid leaks or sensor misalignment. Regular maintenance and adherence to the adjustment flowchart ensure you minimize these issues. For adverse load conditions, recalibrating the hydraulic pressure and inspecting wedge integrity are critical first steps.

Adjustment can be completed within minutes thanks to the hydraulic linkage system, enabling rapid response to production changes without stopping the crusher.

Always monitor hydraulic pressure within specified limits, avoid sudden mechanical movements, and ensure all operators are trained on emergency protocols.

Yes. The system is designed for flexibility to accommodate a range of chemical raw materials such as coal gangue and limestone with different hardness levels, maintaining consistent particle size with minimal downtime.