The dual-wedge discharge opening adjustment featured in the PFW impact crusher by Zhengzhou Mining Machinery Co., Ltd. represents a pivotal advancement in particle size control technology. This article explores the mechanical and hydraulic synergy within the dual-wedge structure that empowers precise, stepless adjustments—vital for optimizing processing of chemical raw materials like limestone and coal gangue. Understanding this innovative mechanism not only improves particle size precision but also promotes automation efficiency across mineral production lines.

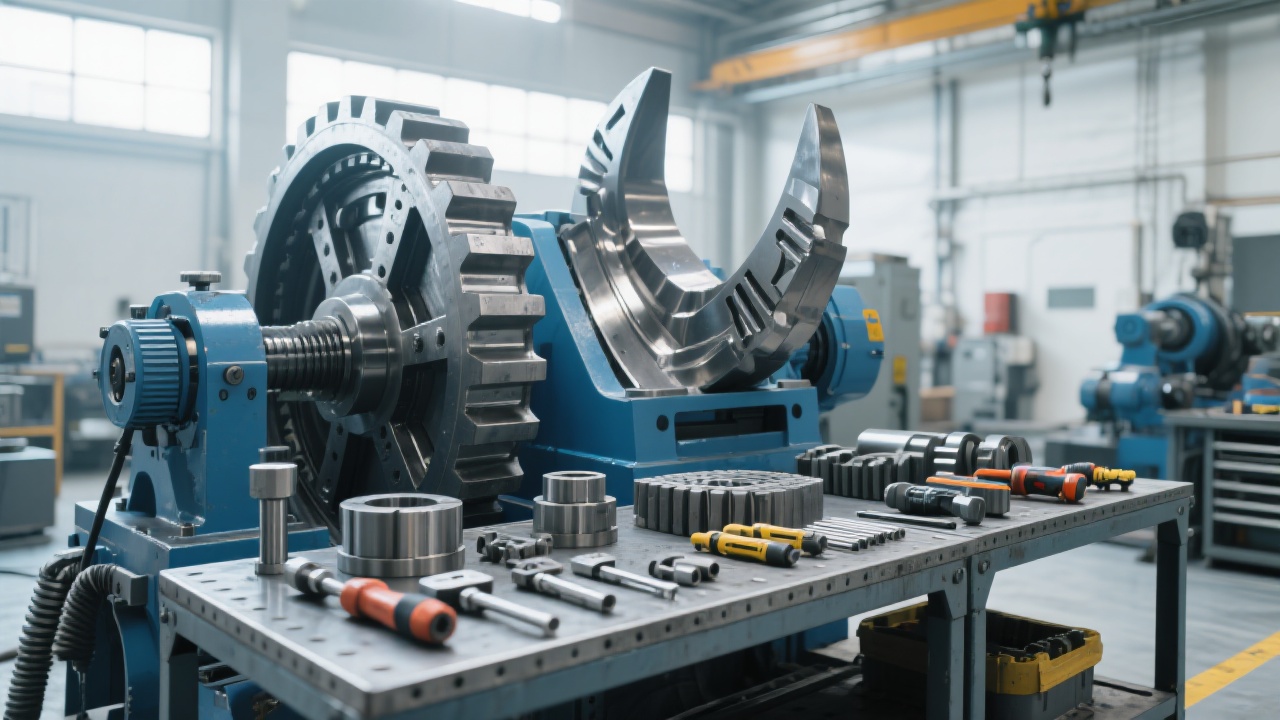

The dual-wedge structure integrates two wedge blocks whose synchronized movement changes the discharge port gap. This adjustment modulates output particle size with high accuracy. Assisting this functionality, the hydraulic system ensures smooth, rapid shifting, while the mechanical linkage guarantees stability during continuous operation. Together, they allow for rapid and non-stepwise alteration, adaptable to dynamic production demands.

Operating parameters such as wedge angle, hydraulic pressure (typically 12-16 MPa), and feedback sensor calibrations are key to achieving optimal particle distribution. Precise setting of these variables can reduce particle size variance by up to 15%, significantly enhancing downstream processing and product quality.

Implementing the dual-wedge adjustment involves a standard sequence:

Implementing thorough calibration reduces adjustment duration typically from 30 minutes to under 10 minutes, translating into minimized downtime and enhanced operational throughput.

Application scenarios in chemical raw material processing validate the dual-wedge system’s efficacy. For example, a limestone quarry using the PFW crusher reported a 20% increase in output uniformity with finer product grading, while a coal gangue recycling plant noted a 25% boost in throughput due to reduced adjustment intervals.

These gains largely result from the mechanism’s ability to maintain precise gap settings even under variable feed size and moisture conditions—common challenges in mineral processing.

Integration with PLC-based control systems enables real-time monitoring of wedge position and discharge gap width, automating adjustment according to predefined granular specifications. This advancement reduces human intervention, limits errors, and allows quick responses to changing feedstock conditions. It also augments data acquisition for predictive maintenance analytics.

Engineers can set automated alerts for threshold deviations, ensuring immediate action, ultimately improving equipment uptime and production quality.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)