In the realm of non - metallic ore crushing, the PEW jaw crusher has emerged as a revolutionary solution, aiming to achieve a dual breakthrough in crushing efficiency and energy - saving. This article is set to provide a comprehensive exploration of the design advantages of its V - shaped crushing chamber, coupled with a real - project data - based test report to address the industry pain points of high energy consumption and low crushing ratio in traditional jaw crushers.

The non - metallic ore crushing process typically consists of three main stages: coarse crushing, medium crushing, and screening. Each stage has its own unique technical requirements. Coarse crushing is the initial step where large ore blocks are broken down into smaller pieces. Medium crushing further refines the size of the crushed materials, and screening separates the materials according to their particle sizes.

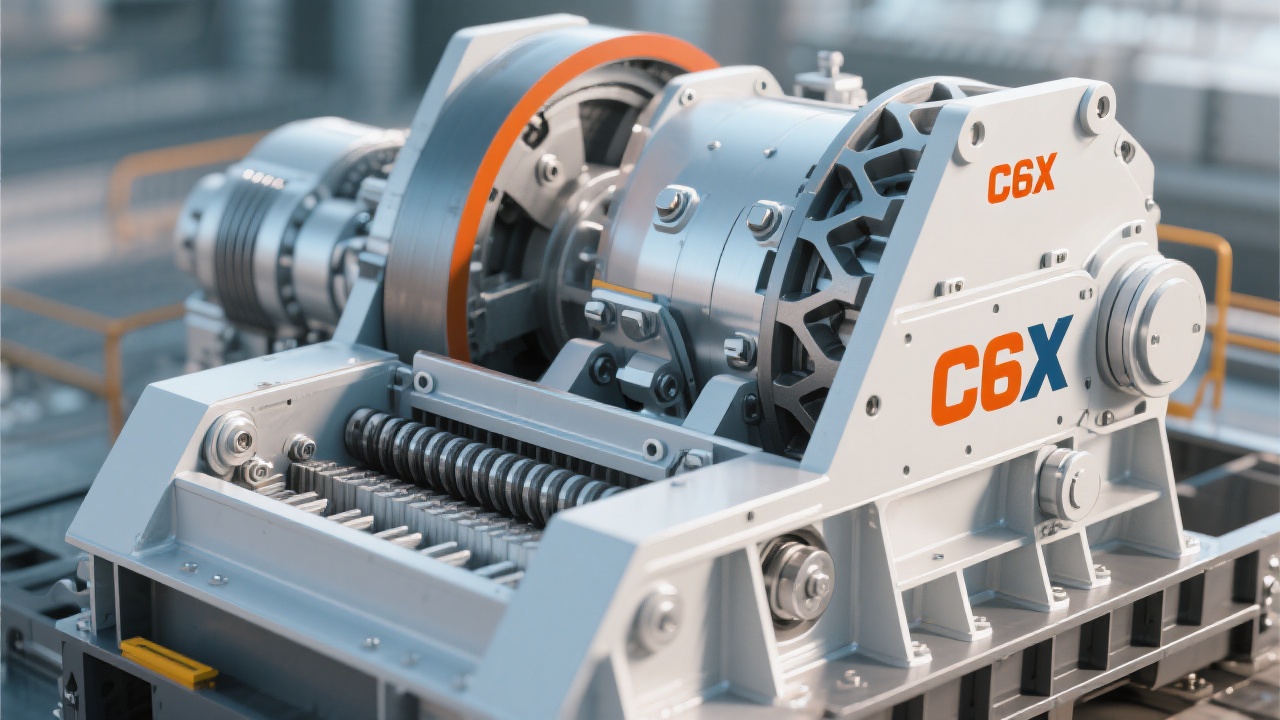

Traditional jaw crushers often suffer from high energy consumption and low crushing ratios. The conventional design of their crushing chambers leads to inefficient force distribution during the crushing process. On the contrary, the PEW jaw crusher features a V - shaped crushing chamber. Data shows that this V - shaped design can improve the crushing ratio by up to 30% compared to traditional jaw crushers. In terms of energy consumption, real - world tests have indicated that the PEW jaw crusher can reduce energy consumption by approximately 20% in the non - metallic ore crushing process.

| Crusher Type | Crushing Ratio | Energy Consumption (kWh/ton) |

|---|---|---|

| Traditional Jaw Crusher | 2 - 3 | 8 - 10 |

| PEW Jaw Crusher | 2.6 - 3.9 | 6.4 - 8 |

Let's take a look at some real - world cases. In a limestone sand - making line, the PEW jaw crusher was configured to work with other equipment. By precisely matching the parameters of the PEW jaw crusher with the subsequent equipment, such as the cone crusher and the vibrating screen, the overall efficiency of the production line was significantly improved. Similarly, in a granite aggregate production line, the proper selection and parameter adjustment of the PEW jaw crusher ensured stable production and high - quality aggregate output.

In non - metallic ore crushing processes, common bottlenecks include over - crushing and blockages. Over - crushing leads to unnecessary energy consumption and a decrease in product quality. Blockages can disrupt the normal operation of the production line. To diagnose these problems, operators can monitor the power consumption, production rate, and particle size distribution of the crushed materials. For over - crushing, adjusting the crushing chamber settings and the feed rate can be effective solutions. In the case of blockages, proper maintenance of the equipment and the use of anti - blockage devices can prevent such issues.

The coordination between different pieces of equipment, such as the cone crusher and the vibrating screen, is crucial for the stability of the overall production line. The cone crusher can further refine the crushed materials from the PEW jaw crusher, and the vibrating screen can accurately separate the materials according to their particle sizes. When these equipment work in harmony, the production line can achieve high - efficiency and stable operation.

During on - site commissioning, it is essential to follow the correct procedures. First, ensure that all equipment is properly installed and aligned. Then, conduct a trial run with a small amount of feed materials to check for any abnormal vibrations or noises. Operators should also pay attention to the lubrication of the equipment, the tightness of the belts, and the temperature of the bearings. By following these precautions, the service life of the equipment can be extended, and the production efficiency can be maintained.

In conclusion, the PEW jaw crusher offers a comprehensive solution for non - metallic ore crushing. Its unique V - shaped crushing chamber design, energy - saving performance, and high crushing ratio make it an ideal choice for industries such as building materials, chemicals, and ceramics. Choosing the PEW jaw crusher is not just about purchasing a piece of equipment; it's an investment in an efficient and sustainable crushing solution. Click here to learn more about how PEW jaw crushers can transform your production line!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)