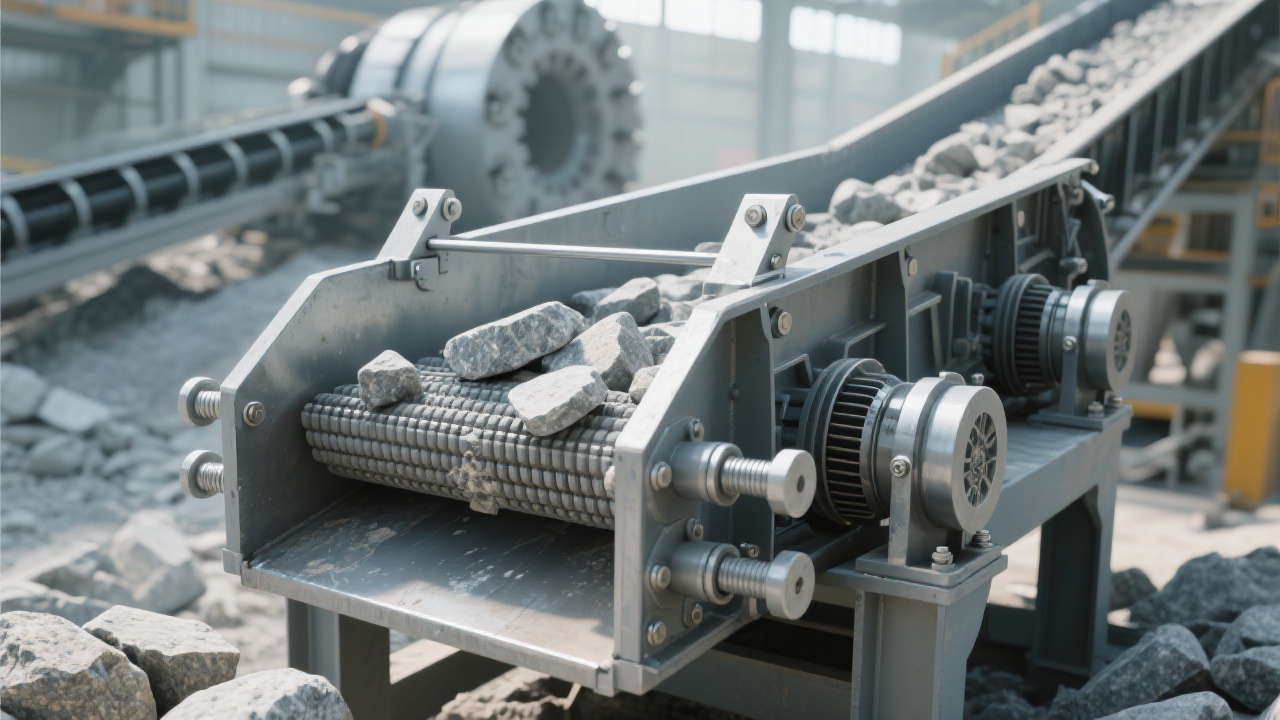

The C6X Jaw Crusher, developed by Zhengzhou Kuanglian Machinery Co., Ltd., is a high - performance crushing equipment widely used in large aggregate plants. Its key technical specifications include a feed opening size ranging from 400mm to 1200mm, which can handle large - sized raw materials. The maximum feeding size can reach up to 85% of the feed opening width, ensuring high - efficiency intake.

In terms of performance, it has a high crushing ratio, generally between 4 and 6. This means that it can effectively reduce the size of large rocks into smaller, more manageable pieces. The production capacity is also remarkable, with an hourly output ranging from 80 tons to 1000 tons, depending on different configurations and operating conditions.

The C6X Jaw Crusher shows excellent adaptability and stability in different types of ore crushing. For example, in hard ore such as granite, its special crushing cavity design and high - strength movable jaw plate can ensure continuous and efficient crushing. The crushing efficiency can reach up to 80% in some cases, which is much higher than traditional crushers.

In soft ore like limestone, the crusher can adjust the crushing force according to the characteristics of the ore, reducing unnecessary energy consumption. The following table shows the crushing performance of C6X Jaw Crusher in different ore types:

| Ore Type | Crushing Ratio | Production Capacity (t/h) | Energy Consumption (kWh/t) |

|---|---|---|---|

| Granite | 5 - 6 | 100 - 500 | 1.5 - 2.5 |

| Limestone | 4 - 5 | 200 - 800 | 1 - 1.5 |

| Iron Ore | 5 - 6 | 150 - 600 | 1.8 - 2.8 |

In the Southeast Asian market, a large - scale aggregate plant in Indonesia purchased the C6X Jaw Crusher. Before using this crusher, the plant's production capacity was only about 300 tons per hour, and the equipment failure rate was as high as 15% per month. After installing the C6X Jaw Crusher, the production capacity increased to 500 tons per hour, and the failure rate dropped to less than 5% per month, significantly improving the economic benefits.

In the Middle East, a quarry in Saudi Arabia used the C6X Jaw Crusher for crushing limestone. The crusher showed excellent stability in the high - temperature and dry environment. The annual production cost was reduced by about 20% due to its high - efficiency operation and low energy consumption.

In Africa, a mining company in South Africa used the C6X Jaw Crusher to crush gold ore. The crusher's high - precision crushing performance improved the gold extraction rate by about 8%, bringing substantial economic benefits to the company.

The C6X Jaw Crusher features an advanced structural design. Its non - welding frame structure is made of high - quality steel castings, which significantly improves the overall strength and stability of the equipment. The use of a large - eccentricity toggle plate design increases the stroke of the movable jaw, thereby improving the crushing efficiency.

In terms of material technology, the movable jaw plate and fixed jaw plate are made of high - manganese steel, which has high wear resistance and long service life. The crushing cavity is also optimized to ensure uniform material distribution and reduce wear.

The intelligent control technology of the C6X Jaw Crusher is another highlight. It can monitor the operating status of the equipment in real - time, such as temperature, vibration, and load. Once an abnormal situation is detected, it can automatically adjust the operating parameters or issue an alarm, reducing the risk of equipment damage.

For operators, it is necessary to carefully read the operation manual before installation and commissioning. Ensure that the installation foundation is firm and the equipment is level. During the commissioning process, gradually increase the feed rate to avoid overloading.

For managers, they should establish a regular maintenance plan. Check the wear of key components such as jaw plates and toggle plates regularly and replace them in time. At the same time, optimize the production process according to the actual production situation to improve overall efficiency.

For purchasers, they should consider the long - term cost, including energy consumption, maintenance cost, and replacement parts cost. The C6X Jaw Crusher, with its high - efficiency operation and low maintenance cost, is a cost - effective choice.

With the development of the aggregate industry, there is an increasing demand for high - efficiency, low - energy - consumption, and intelligent crushing equipment. The C6X Jaw Crusher is constantly upgrading its technology to meet these requirements. For example, future upgrades may include more advanced intelligent control systems and more wear - resistant materials.

The future application potential of the C6X Jaw Crusher is huge. It can be widely used in new construction projects, road building, and the recycling of construction waste. Choosing the C6X Jaw Crusher means investing in a high - performance and forward - looking equipment that can bring long - term production efficiency and economic benefits.

Do you have any questions about the C6X Jaw Crusher? Are you facing similar problems in your aggregate plant? Please feel free to leave your questions below. If you want to know more about the C6X Jaw Crusher and get more industry - specific solutions, click here.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)