In the metal ore processing chain, the efficiency of primary crushing directly influences downstream operations like grinding, classification, and mineral recovery. A well-designed PE jaw crusher + secondary crusher (impact or cone) system isn't just about breaking rock—it’s about creating a seamless flow that maximizes yield while minimizing energy waste.

Most mining projects see raw feed sizes ranging from 300mm to over 1000mm. When this range is not properly managed, it leads to inconsistent throughput, premature wear on downstream equipment, and missed opportunities for fine-grained liberation. By targeting a controlled input of 0–1020mm through precise coarse crushing, operators can ensure:

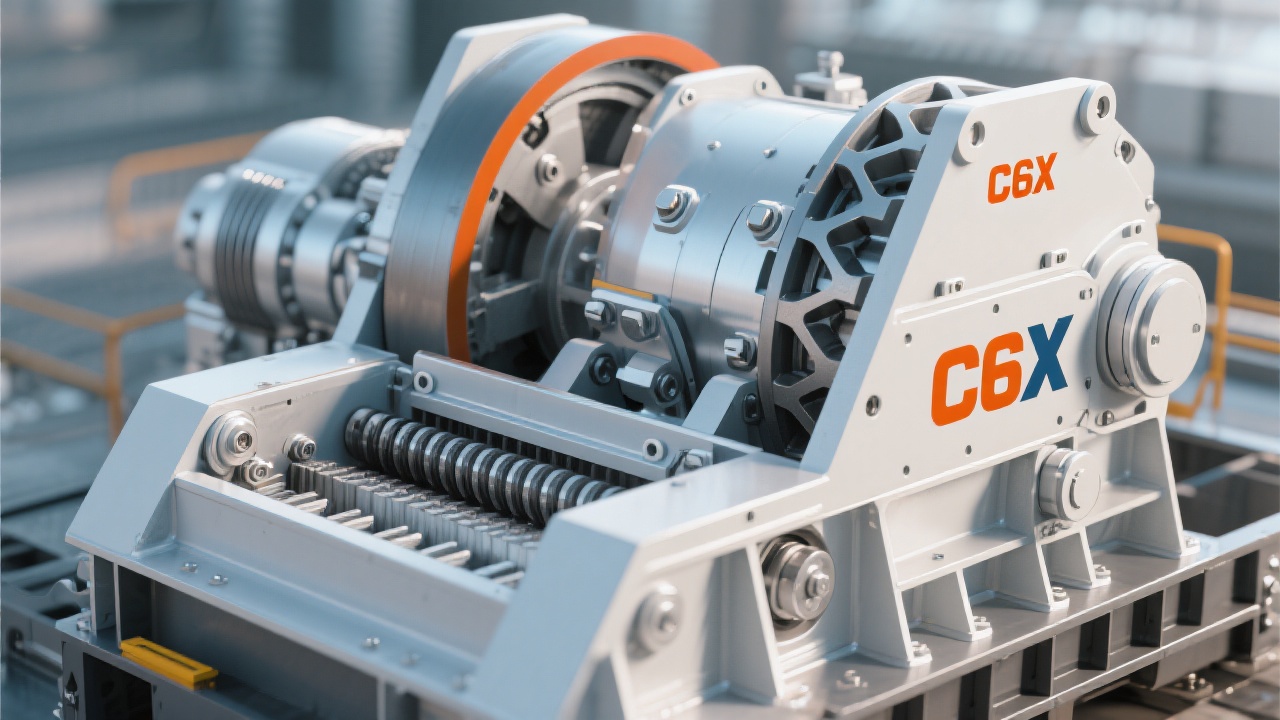

The key lies in matching the right primary breaker with a compatible secondary unit based on ore hardness, moisture content, and production goals. For instance:

| Application | Recommended Setup | Expected Outcome |

|---|---|---|

| Hard Rock (e.g., Copper) | PE jaw + HP cone crusher | +9% recovery vs. single-stage |

| Semi-hard / Wet Ore (e.g., Gold) | PE jaw + impact crusher | +12% throughput, less blockage |

These configurations are not one-size-fits-all—they must be tailored to site-specific conditions. That’s where our customized solutions come in: we don’t sell machines—we build systems optimized for your ore type, climate, and operational rhythm.

African Copper Mine (Zambia): After implementing a coordinated PE jaw + cone setup with smart screening, dust control via water misting, and belt conveyor optimization, they achieved a 6.3% increase in copper recovery within six months—while reducing specific energy consumption by 11%. The mine now runs 24/7 without downtime due to screen clogging.

Similarly, a gold project in Peru saw improved classifier performance after switching from a standalone jaw crusher to a two-stage system. Their tailings grade dropped from 0.8 g/t to 0.4 g/t—a direct result of better particle size distribution from the initial breakage stage.

What these cases reveal: when you treat crushing as part of an integrated process—not just a step—you unlock gains across the entire operation. From reduced maintenance costs to cleaner emissions, the benefits compound quickly.

We’ve helped over 200 mines worldwide—from small-scale operations in Indonesia to large plants in Chile—optimize their crushing lines using real-time data analytics and predictive maintenance tools. Our global service network ensures fast response times, even in remote regions. And with every machine shipped, we include full documentation, training, and lifetime technical support.

If you're ready to turn your crushing stage into a competitive advantage—not just a bottleneck—let’s talk.

Get Your Customized Crushing System Plan Today