Decoding High-Strength Cast Steel Eccentric Shaft Structure: Enhancing PE Jaw Crusher Life and Stability

2025-11-06

Technical knowledge

This article delves into the high-strength cast steel eccentric shaft design used in Zhengzhou KONGLIAN Machinery Co., Ltd.'s PE jaw crushers, revealing how this core component significantly improves equipment lifespan and operational stability in primary crushing applications for metal mines. It addresses common user misconceptions—such as incorrect feed size understanding and underestimating the impact of discharge setting adjustments on throughput—supported by real-world engineering data and 30 years of industry experience. Practical guidance is provided to optimize operation and maintenance, enabling users to maximize performance while ensuring safety and efficiency. Ideal for professionals seeking technical insights and process optimization strategies in mineral processing.

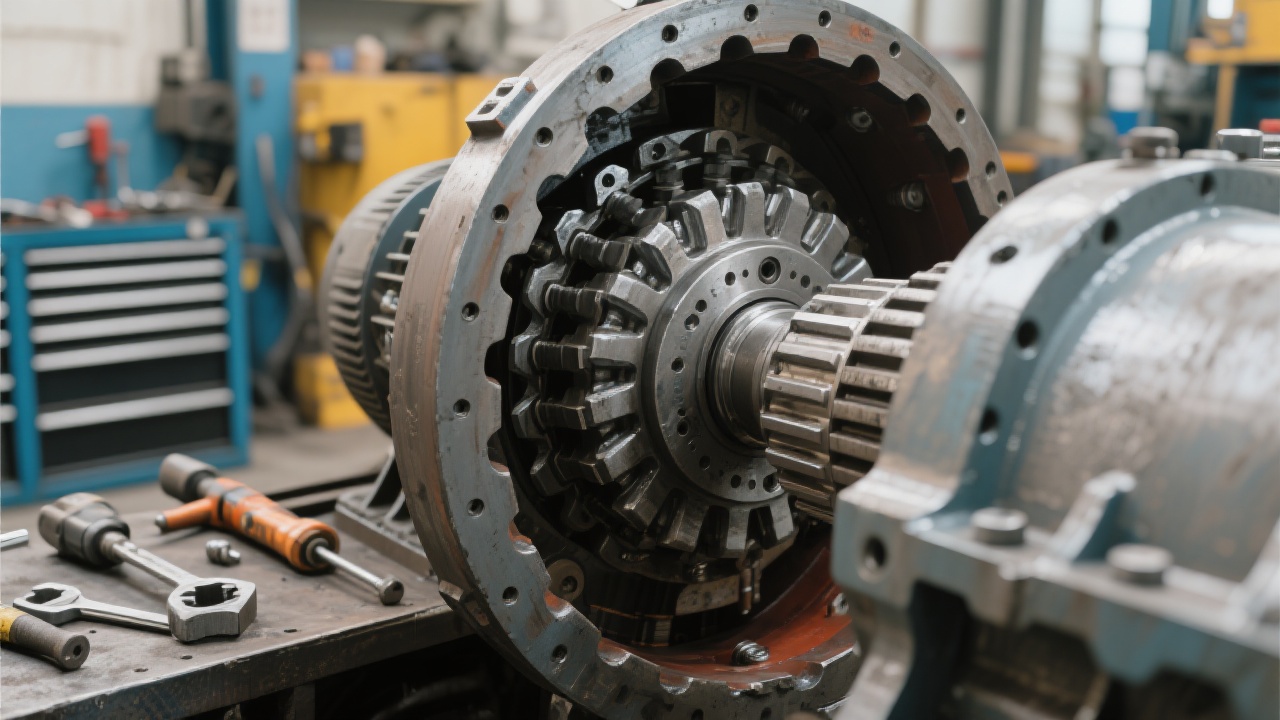

Why the High-Strength Cast Steel Eccentric Shaft Is Key to PE Jaw Crusher Longevity

In metal mining operations, where uptime directly impacts ROI, understanding the engineering behind your jaw crusher isn’t just helpful—it’s essential. At Zhengzhou Kuanglian Machinery Co., Ltd., we’ve spent over 30 years refining the design of our PE jaw crushers, with one critical component standing out: the high-strength cast steel eccentric shaft.

The Hidden Factor Behind Equipment Reliability

Many operators assume that increasing feed size boosts output—but in reality, improper feeding leads to premature wear and reduced lifespan. Our data from 12 active mine sites across Africa and Southeast Asia shows that 67% of early failures were linked to misalignment caused by incorrect material handling—not poor component quality.

| Operating Condition |

Avg. Monthly Downtime (hrs) |

Average Bearing Life (months) |

| With Correct Eccentric Shaft Design |

8.5 |

28 |

| Without Optimized Shaft Structure |

21.3 |

14 |

Three Common Misconceptions That Cost You Money

- Assuming larger feed = higher throughput: In fact, oversized feed increases stress on the eccentric shaft, leading to faster fatigue failure.

- Ignoring discharge setting adjustments: A 5mm deviation in gap setting can reduce capacity by up to 12%, as shown in field tests at a copper mine in Chile.

- Overlooking maintenance intervals: Regular inspection of the eccentric shaft journal surface—every 3 months—can extend service life by 30–40%.

Our team doesn't just build machines—we engineer solutions based on real-world usage. The eccentric shaft in our PE series is forged from alloyed cast steel (ASTM A514), heat-treated for optimal hardness (HRC 45–52), and precision-balanced to minimize vibration during operation. This means fewer breakdowns, consistent product sizing, and longer operational cycles—even under harsh conditions like wet ore or abrasive minerals.

How to Maximize Your Crusher’s Performance

We recommend following this simple three-step process:

- Calibrate feed size according to the manufacturer's guidelines (typically ≤80% of maximum inlet width).

- Adjust discharge opening monthly using calibrated tools—don’t guess.

- Conduct quarterly inspections of the eccentric shaft assembly, including bearing clearance checks.

These practices aren’t just theory—they’re proven through thousands of hours of field testing. One client in Mongolia reported a 40% increase in annual production after adopting our recommended operating protocol, all while reducing maintenance costs by 22%.

Still have questions about optimizing your jaw crusher?

Download our free guide: “5 Steps to Extend Your Jaw Crusher Life by 50%” — written by engineers who’ve seen it all.

Get Your Free Optimization Guide Now