In the realm of metal ore mining, primary crushing is a critical stage that directly impacts downstream processes and overall productivity. The PE jaw crusher, renowned for its robust construction and efficiency, stands out as a cornerstone equipment in initial ore size reduction. This article dissects the key technological advantages and operational best practices of PE jaw crushers, with a sharp focus on optimizing performance, reducing energy consumption, and navigating common user misconceptions.

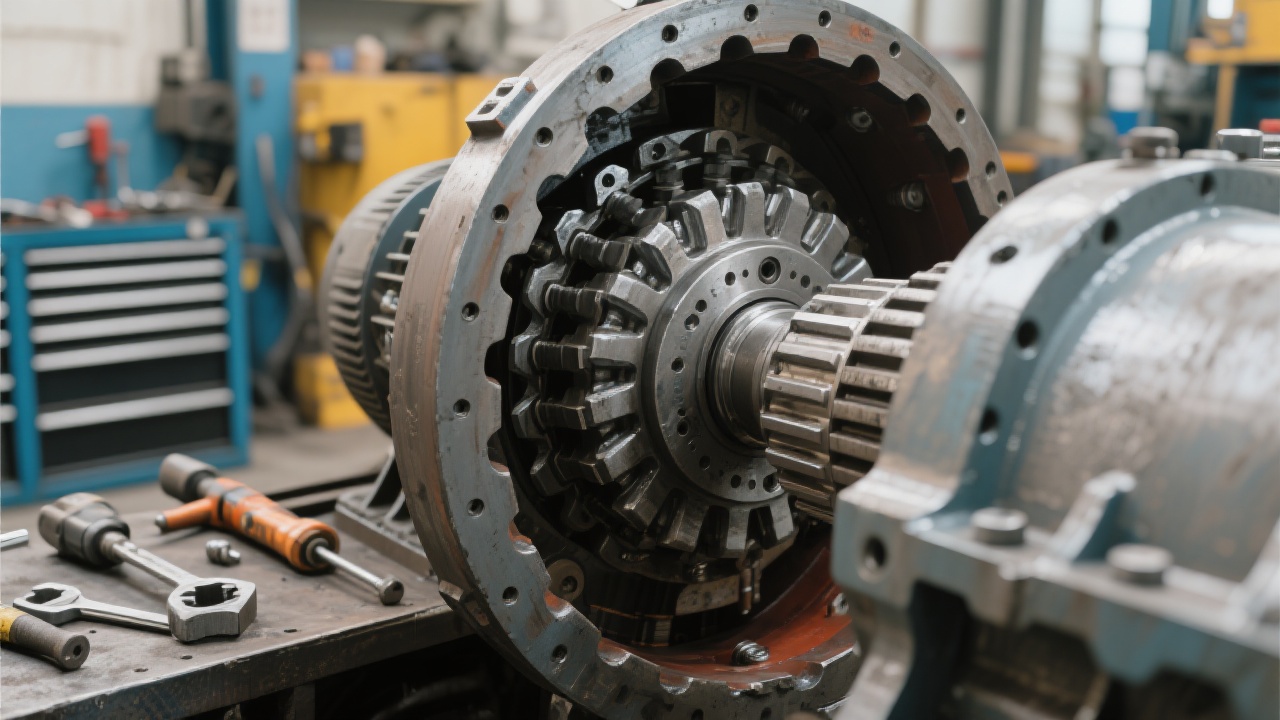

Metal ore deposits worldwide exhibit vast variability in hardness, moisture content, and abrasiveness. As a result, primary crushers must adapt to a spectrum of conditions. PE jaw crushers fulfill this demand through a robust design featuring high-strength materials and customizable settings. Industries including copper, iron, and precious metal mining rely on these machines to consistently deliver coarse crushing with high throughput rates — often reaching capacities between 50 to 1000 tons per hour.

Yet, despite their proven track record, operators often face challenges such as fluctuating output and elevated power usage. Addressing these pain points requires a detailed understanding of the equipment’s mechanical and operational parameters.

| Challenges | Impact | Common Causes |

|---|---|---|

| Unstable production outputs | Inconsistent material flow and scheduling delays | Improper setting of discharge port and inconsistent feeding |

| High energy consumption | Increased operational costs | Excessive crushing ratio and overloading |

| Frequent wear and maintenance downtime | Reduced availability and repair expenses | Ignoring material moisture and irregular maintenance |

An excessively high crushing ratio may intuitively seem beneficial, but in practice, operating a PE jaw crusher beyond its optimal ratio (typically 4:1 to 6:1) leads to machine strain and uneven wear. Real project data from a copper mine demonstrated a 15% drop in throughput when crushing ratios exceeded 6:1, with energy consumption soaring by over 12%.

Moisture levels above 8% drastically affect crushing efficiency due to clogging and increased abrasion. Mines observed a 10-20% reduction in jaw crusher effective runtime without timely moisture control measures.

Delay in routine inspections of the high-strength cast steel eccentric shaft and unadjusted discharge port systems can accelerate wear and cause unexpected breakdowns. Data from several iron ore processing plants show that rigorous maintenance schedules extend component life by up to 30% and reduce downtime by 25%.

Advanced engineering of PE jaw crushers is centered on three pillars:

Manufacturers and industry experts recommend the following best practices:

| Action | Recommended Frequency | Expected Benefit |

|---|---|---|

| Adjust discharge port to maintain product size tolerance | Daily or Per Material Batch | Improved product uniformity and throughput stability |

| Inspect and lubricate eccentric shaft bearings | Weekly | Reduced wear and extended shaft service life |

| Monitor and control feed moisture levels | Ongoing | Lower clogging rates and enhanced crushing efficiency |

To maximize visibility and user engagement, deploying long-tail keywords such as “PE jaw crusher adjustment methods for metal ore”, “preventing high energy consumption in jaw crushers”, and “primary crushing equipment maintenance tips” is essential. Coupled with infographics and video demonstrations, this content structure supports higher search rankings and improved click-through rates.

We invite users to submit their operational questions or share case studies through the comments section below. Our commitment to a dynamic technical knowledge base ensures the latest practices and solutions are integrated, fostering a collaborative environment.

.jpg)