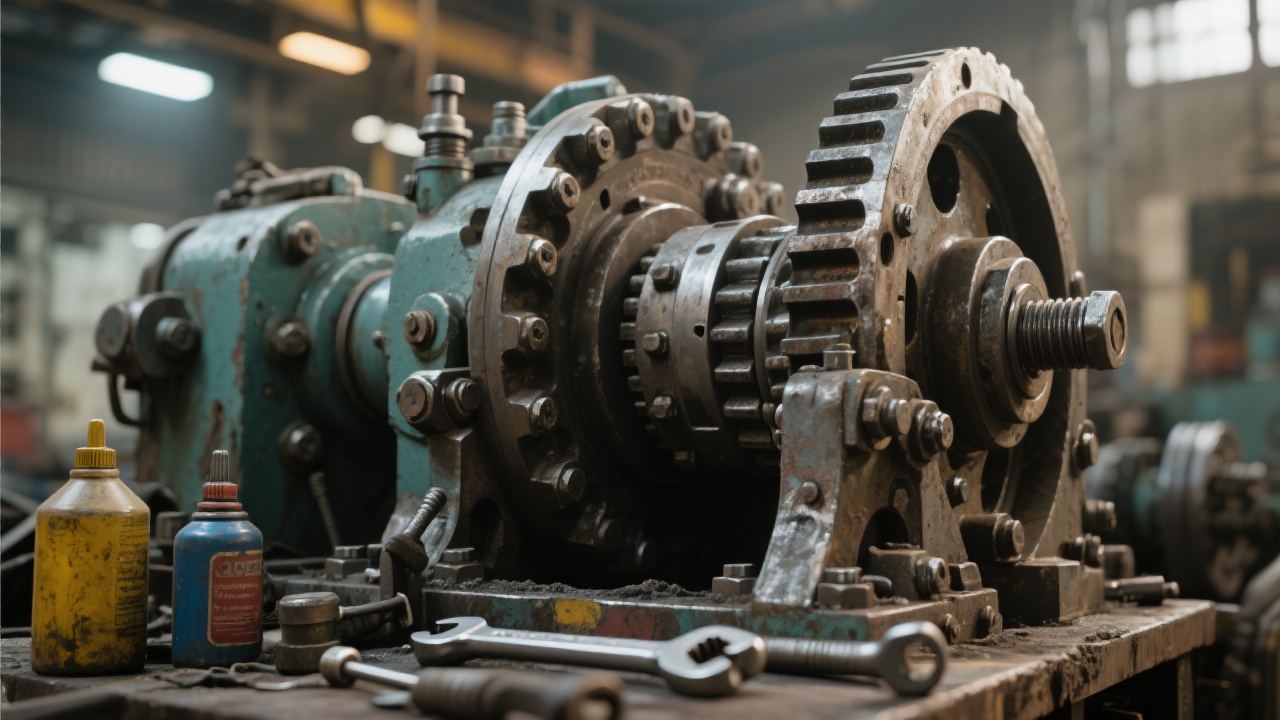

In the metal ore crushing industry, operators often encounter a series of challenges that can significantly impact production efficiency and equipment lifespan. From uneven feeding to high mud content and rapid liner wear, these issues can lead to blockages, unstable output, and increased maintenance costs. Let's delve into the root causes of these problems and explore how Zhengzhou Kuanglian's PEW Jaw Crushers offer effective solutions.

One of the primary issues in metal ore crushing is uneven feeding. When the ore is not fed evenly into the crusher, it can cause overloading in certain areas, leading to increased wear on the crusher components and reduced overall efficiency. Another common problem is the high mud content in the ore. Mud can clog the crusher, reduce the crushing efficiency, and increase the wear on the liners. Additionally, the wear of the liners is a major concern. Over time, the liners can wear out, leading to a decrease in the crushing performance and an increase in the production of fines.

To illustrate these problems, consider the following data. In a typical metal ore crushing plant, uneven feeding can result in a 15 - 20% reduction in crushing efficiency. High mud content can cause a 10 - 15% decrease in output and a 20 - 30% increase in liner wear. These figures highlight the significant impact of these problems on the production process.

The PEW Jaw Crushers from Zhengzhou Kuanglian are designed to address these challenges. The V - shaped crushing chamber is one of the key structural advantages of the PEW series. This design allows for a more uniform distribution of the ore during the crushing process, reducing the uneven wear caused by uneven feeding. The use of wear - resistant alloy materials in the liners and moving jaw plates further enhances the durability of the crusher. These materials can withstand the high - impact forces and abrasion associated with metal ore crushing, significantly extending the service life of the components.

According to an engineer's practical experience (quoted in the following block):

"In a copper ore crushing project, we replaced the traditional liners with the wear - resistant alloy liners of the PEW Jaw Crusher. The liner replacement frequency was reduced from once every 2 months to once every 6 months, which greatly improved the production stability and reduced the maintenance cost."

Early detection of potential problems is crucial for maintaining the continuous and stable operation of the crusher. By monitoring the vibration frequency and current fluctuations, operators can identify early signs of abnormal operation. For example, an increase in vibration frequency may indicate a problem with the alignment of the crusher components or excessive wear. A sudden change in current may suggest a blockage or overloading. In a real - world scenario, a gold ore crushing plant was able to detect a potential blockage in the crusher by monitoring the current fluctuations. By taking timely measures, they were able to avoid a major breakdown and ensure the continuous operation of the production line.

The preventive maintenance mechanism of the PEW Jaw Crusher is also a significant advantage. The intelligent material - clearing function can automatically remove the clogged materials, reducing the downtime caused by blockages. This function, combined with regular maintenance, can ensure the continuous and stable operation of the crusher.

.jpg)

Let's look at a case study from an iron ore crushing plant. After installing the PEW Jaw Crusher, the plant was able to increase the crushing efficiency by 25%, reduce the liner replacement frequency by 40%, and achieve a 15% reduction in energy consumption. This case clearly demonstrates the effectiveness of the PEW Jaw Crusher in improving the production process.

We encourage you to share your experiences and questions in the comment section below. Have you encountered similar problems in your metal ore crushing operations? How do you think the PEW Jaw Crusher can help you solve these problems? By participating in this discussion, you can learn from others' experiences and gain valuable insights into the best practices in metal ore crushing. Click here to explore more about Zhengzhou Kuanglian's PEW Jaw Crushers and take your metal ore crushing process to the next level.

Do you have any other questions about the PEW Jaw Crushers or metal ore crushing? Leave your questions in the comments, and our experts will be happy to answer them!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)