In the field of metal ore crushing, technical challenges are common. For example, blockages can occur in the crushing process, which may reduce the production efficiency by up to 30%. Liner wear is another significant issue, and it can lead to an increase in maintenance costs by about 20%. Moreover, fluctuations in production volume can disrupt the stable operation of the production line.

These problems are caused by multiple factors. In terms of material characteristics, ores with high moisture content or complex compositions are more likely to cause blockages. Regarding equipment parameters, if the crusher's discharge opening is not properly adjusted, it may lead to uneven material flow and subsequent blockages. Improper operation habits, such as over - feeding, can also exacerbate these problems.

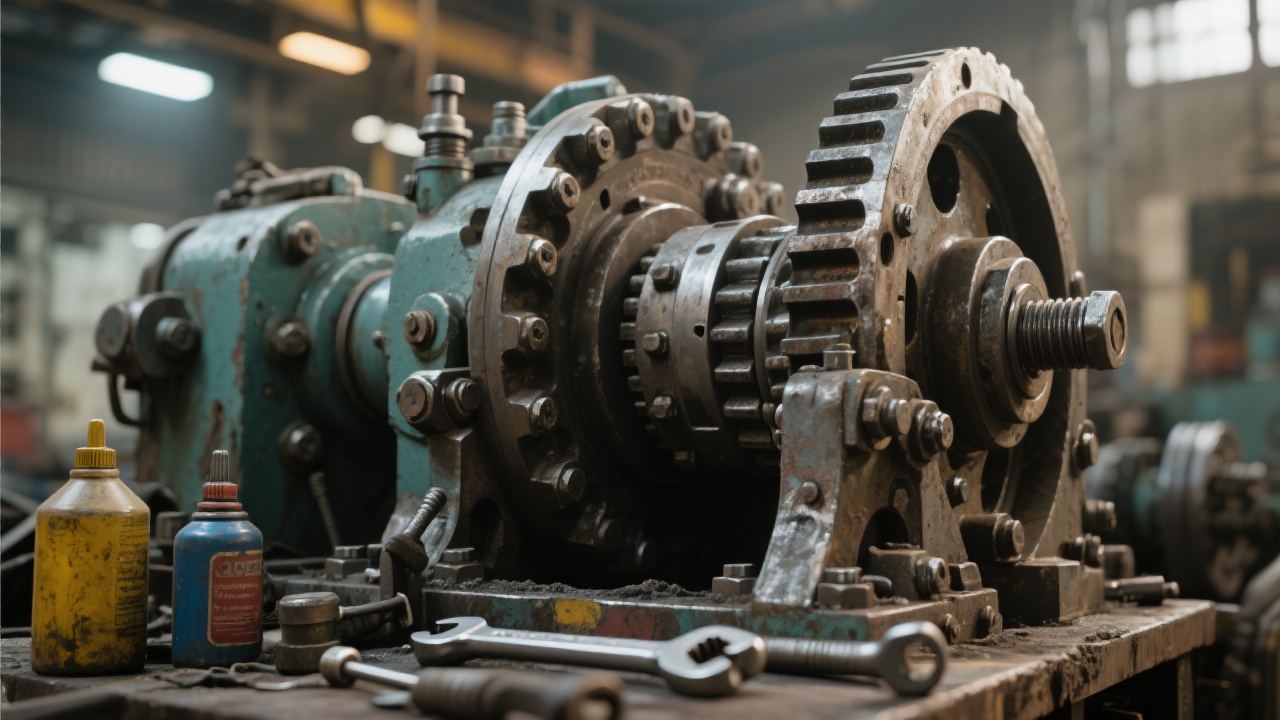

Zhengzhou Kuanglian's PEW Jaw Crusher has several structural advantages. Its unique crushing chamber design ensures a more efficient crushing process. The use of high - quality wear - resistant materials significantly extends the service life of the liner, reducing the frequency of liner replacement from once every three months to once every six months.

The crusher also features intelligent control systems. For example, it can monitor the load in real - time and adjust the feeding speed accordingly, which helps to maintain a stable production volume. In addition, its advanced lubrication system ensures smooth operation and reduces friction losses.

Install sensors at the feed inlet and discharge outlet to monitor the material flow. If the flow rate decreases abnormally, the system can issue an alarm and automatically adjust the feeding speed. For example, in a certain mine, after implementing this measure, the frequency of blockages was reduced by 40%.

Regularly measure the thickness of the liner. When the wear reaches a certain level, replace the liner in time. Also, adjust the crusher's parameters according to the wear condition to ensure stable crushing performance. A mine in Africa achieved a 15% reduction in processing costs by effectively managing liner wear.

Use the intelligent control system of the PEW Jaw Crusher to adjust the feeding speed and crusher operation parameters in real - time according to the production demand. In a domestic mine, this measure helped to reduce the production volume fluctuation range from ±15% to ±5%.

The PEW Jaw Crusher is equipped with a remote monitoring system. Through this system, engineers can monitor the equipment's operating status in real - time, detect potential problems in advance, and carry out preventive maintenance. For example, by analyzing the vibration data of the crusher, engineers can predict the wear of key components and replace them before they cause serious failures.

A mine in South America was facing serious blockage problems in its crushing process. After using the Zhengzhou Kuanglian PEW Jaw Crusher and implementing the corresponding efficiency - improvement measures, the crushing efficiency increased by 25%, and the production line's stable operation time increased from 20 days per month to 25 days per month.

Do you have any questions about metal ore crushing or the application of the PEW Jaw Crusher? Feel free to leave your questions in the comments section below. We will answer them as soon as possible. Also, if you share your experiences in the industry, you can get 3 case studies of improving crushing efficiency from similar mines.

Explore more about how the Zhengzhou Kuanglian PEW Jaw Crusher can enhance your ore - crushing operations. Click here to learn more.

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)