.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

In the demanding environment of metal ore processing, crushing equipment faces persistent challenges such as frequent blockages, accelerated wear, and inconsistent output. These issues often stem from uneven feed distribution, high mud content in ore, and suboptimal machine parameter settings. Zhengzhou Kuanglian’s PEW series jaw crusher addresses these operational obstacles with innovative mechanical design and integrated smart maintenance technology, helping mining operations achieve higher efficiency and prolonged equipment lifespan.

Metal ore crushing is complex due to the material's diverse characteristics and harsh working conditions. Common disruptions include:

Investigations identify three main contributors:

The hallmark of the PEW jaw crusher is its patented “V” type crushing chamber, a design optimized for reduced material blocking and improved throughput. This geometry facilitates:

| Feature | Benefit |

|---|---|

| Steep Crushing Chamber Depth | Maintains optimal material flow, reducing feed blockages by up to 15% |

| Wider Feed Opening | Supports larger feed size and accommodates inconsistent feed distribution |

| Optimized Stroke Length | Enhances crushing capacity by approximately 20% |

Field tests have shown throughput increases of 10%-25% compared to traditional jaw crushers, with significantly fewer instances of clogging during high mud content ore processing.

Wear is a primary cost driver in crushing operations. The PEW jaw crusher incorporates premium grade manganese steel and high chromium alloy jaw plates known for their superior abrasion resistance and toughness. Key highlights include:

These enhancements not only preserve crusher performance but also lower total cost of ownership (TCO) by limiting unplanned maintenance and spare part consumption.

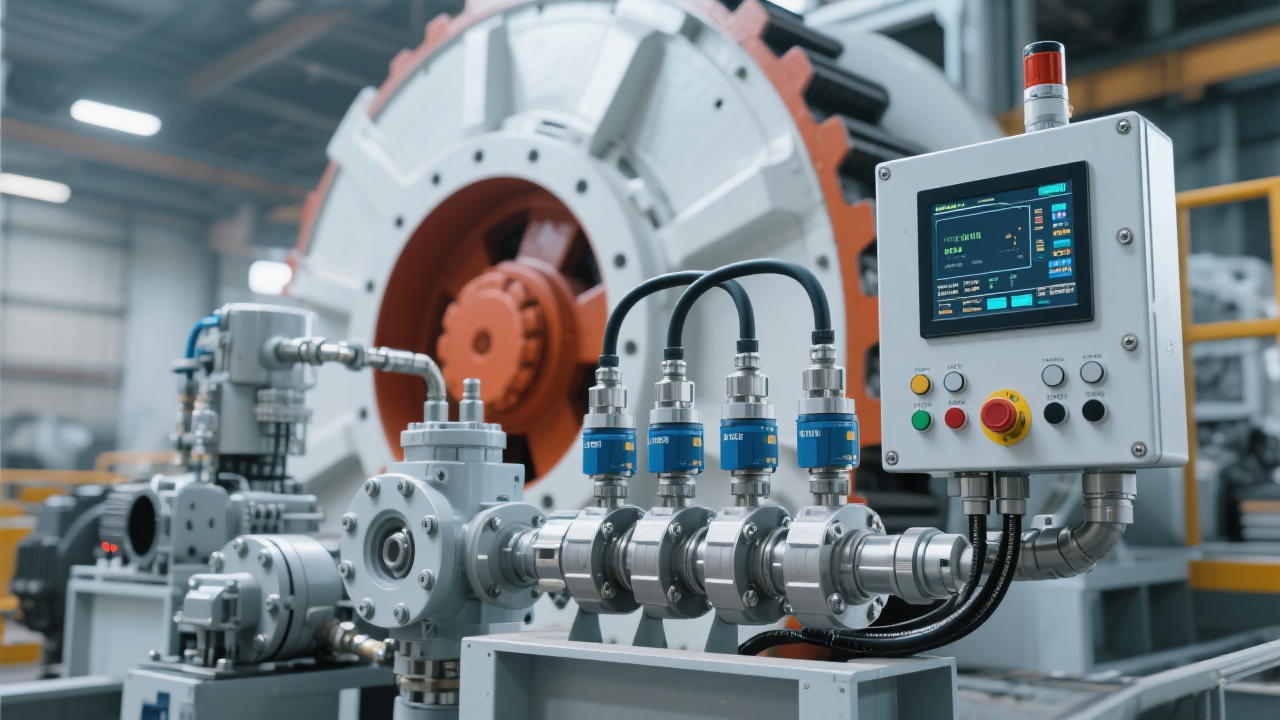

Adopting smart technology into mineral processing equipment is a pivotal trend. Zhengzhou Kuanglian’s PEW jaw crusher integrates an intelligent monitoring system that:

This proactive approach empowers mineral processing teams to implement timely preventive maintenance, minimizing unexpected shutdowns and optimizing production continuity. Internal case studies demonstrated a 25% decline in emergency repairs after system adoption.

.jpg)

Based on on-site feedback from experienced technical engineers and plant managers, critical operational tips include:

These actionable strategies complement the advanced engineering of PEW crushers, maximizing equipment availability and crushing efficiency.

| Advantage | Operational Impact | Value Delivered |

|---|---|---|

| “V”-type Crushing Chamber | Lower clogging incidents; elevated throughput | Up to 25% higher productive capacity |

| Wear-resistant Materials | Longer jaw plate life; reduced maintenance | 30% longer component lifespan |

| Intelligent Maintenance System | Proactive fault detection; maintenance scheduling | 25% reduction in emergency downtime |

Mining enterprises aiming for consistent, high-quality crushing performance will find Zhengzhou Kuanglian’s PEW series jaw crusher a robust solution combining engineering breakthroughs with smart industry 4.0 technology.

Discover How PEW Jaw Crusher Can Transform Your Mining Productivity Today

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)