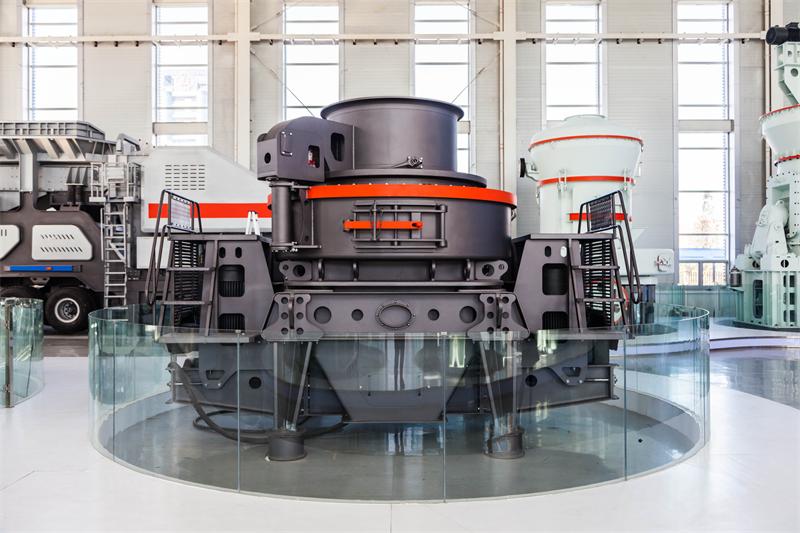

The VSI6X sand - making machine is a revolutionary piece of equipment in the sand - making and shaping industry. It is designed to handle a wide range of materials, including granite, basalt, limestone, quartz, and more. This versatility makes it an ideal choice for various global construction and mining projects.

Developed as an optimization of the traditional vertical shaft impact crusher, the R & D team behind the VSI6X sand - making machine aimed to address the inefficiencies and limitations of previous models. After years of research and development, this advanced machine was born, bringing a new era to the sand - making industry.

The VSI6X sand - making machine is equipped with several patented technologies. These innovations not only enhance the overall performance of the machine but also set it apart from its competitors. For example, the unique crushing chamber design improves the impact force and reduces energy consumption. On average, it can save up to 30% of energy compared to traditional models.

The key components of the VSI6X sand - making machine are carefully designed for durability and high - efficiency. The impeller, a crucial part of the machine, is made of high - strength and wear - resistant materials. As a result, the service life of the impeller is extended by up to 50%, which significantly reduces the maintenance cost and downtime.

The VSI6X sand - making machine can produce high - quality sand at a much faster rate. It can process up to 500 tons of materials per hour, which is 20% more than similar products in the market. The well - shaped sand particles produced by this machine are suitable for various applications, such as concrete production and asphalt mixing.

In addition to energy savings, the VSI6X sand - making machine reduces the cost of spare parts replacement. With its long - lasting key components, the overall cost of ownership is decreased by approximately 25%. This makes it a cost - effective choice for global procurement.

Thanks to the high - quality materials and advanced manufacturing processes, the VSI6X sand - making machine has a longer service life. On average, it can operate continuously for over 20,000 hours without major breakdowns, providing reliable performance for long - term projects.

The machine is designed with multiple safety features. For example, it has an automatic overload protection system that can stop the machine immediately in case of abnormal operation, ensuring the safety of operators and the equipment itself.

The VSI6X sand - making machine supports two feeding modes: full - center feeding and center - periphery feeding. This flexibility allows users to adjust the feeding method according to different materials and production requirements.

In terms of service, a comprehensive after - sales service system is provided. This includes technical support, spare parts supply, and on - site maintenance. The company also offers a one - year warranty for the machine, giving global buyers peace of mind.

A construction project in Africa used the VSI6X sand - making machine. Before using this machine, the project spent a large amount of money on importing high - quality sand. After the installation of the VSI6X sand - making machine, the project was able to produce sufficient high - quality sand on - site, reducing the cost by 40% and shortening the construction period by 30%.

The VSI6X sand - making machine, with its advanced technology, high efficiency, and cost - effectiveness, is the ideal choice for your sand - making needs. Don't miss out on this opportunity to improve your production capacity and reduce costs. Contact us today to learn more and place your order!

.jpg?x-oss-process=image/resize,h_800,m_lfit/format,webp)